The inerting pressure is very low, slightly higher than atmospheric, and has to be precisely controlled to create the optimum environment for sanitary processing. The interting gas is added to the tank and as the tank pressure reaches its desired setpoint, the tank blanketing valve – a back pressure regulator (BPR) or “de-padding” valve – opens to keep the pressure at the exact setpoint. The de-padding valve is often of sanitary design when used in food and biopharmaceutical processes. Sanitary tank blanketing valves can be made with USP Class VI materials or FDA approved materials depending on the process. An Equilibar FDO back pressure regulator (BPR) is a good fit for a sanitary tank blanketing valve due to its instantaneous response and precision low pressure control.

How an FDO sanitary valve works for sanitary tank blanketing

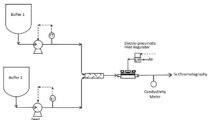

In the schematic below, an FDO sanitary BPR is used in a bioprocessing application controlling the tank headspace pressure where nitrogen is used as the inert blanketing gas. Sparge gas is introduced at the bottom of the tank into the process media for proper cell growth. Nitrogen gas is added to the top of the tank.

Temperature or level changes to the process media as well as gas sparging result in pressure fluctuations inside the tank. Because the environment during bioprocessing is critical to the quality of the final product, the pressure must be precisely maintained. The unique design of the FDO allows it to respond instantaneously to pressure changes during the process and control the pressure at the very low setpoint requirements for this application.

The Equilibar BPR is dome-loaded with pilot operation and uses a supple diaphragm over a field of multiple orifices to create a pressure balance. The patented design results in a very sensitive back pressure regulator capable of maintaining stable pressure at extremely low ranges down to inWC/mbar pressures. Compared to traditional spring solutions, they offer ultra-low pressure control without exhibiting over-pressure behavior. The Equilibar FDO will adjust instantaneously to changes in pressure inside the tank without hysteresis or cracking pressure. They work across a wide range of flow rates and are preferred over traditional valves for their Cv rangeability.

Equilibar FDO sanitary back pressure regulators are fast, accurate and easy to maintain, making them an excellent choice in this application.

In processes that do not require the use of sanitary valves, Equilibar has standard back pressure regulators equally as precise for tank blanket control. Either model would work well for API tank blanketing applications.

Contact an Equilibar application engineer for more information.

FD Series Sanitary back pressure regulator ( product details)