Equilibar now has a new Ultra Low Flow BPR rated to 20,000 psig / 1375 bar(g), called the U20L, that is integrated into DCI Test Systems ABPR-20.

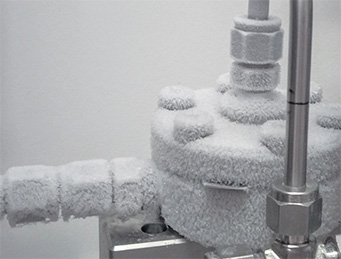

The BPR shown at right, the H10P, is rated for 10,000 psig / 689 bar(g). Because Equilibar regulators are dome-loaded, a pilot setpoint reference pressure is required on the dome reference port equal to the desired inlet pressure (1:1 ratio). This pilot setpoint is typically supplied from high-pressure inert gas bottles, such as nitrogen. Customers generally use a manual pressure reducing regulator to control this reference setpoint, but there are other ways to pressure load the dome of an Equlibar BPR.

| Maximum Pressure, psig / bar(g) | Standard Low Flow Multi-Orifice Series | Single Orifice Ultra Low Flow Series |

|---|---|---|

| 1000 psig 68 bar(g) | LF | U3L |

| 3000 psig 206 bar(g) | H3P | |

| 6000 psig 413 bar(g) | H6P | U6L |

| 10,000 psig 689 bar(g) | H10P | U10L |

For port sizes larger than 1/4″, see our GS Series products, which are available up to 3000 psig / 206 bar(g).

Equilibar BPRs offer high precision in complex applications

The H10P (above) and U10L (below) back pressure regulators are rated up to 10,000 psig / 689 bar(g) service.