Accurate Vacuum Control for High Speed Canning and Filling

High speed canning and filling operations depend on accurate vacuum control to provide reliable performance. Vacuum control serves several key purposes, including:

- To rapidly draw liquid product into a can in a short time frame

- To minimize splashing from container by minimizing outflow of air

- To prevent collapse of modern thinner can walls by avoiding excessive vacuum

Vacuum pumps are used to draw out the air from the can or bottle just prior to filling. Depending on the type of pump, the approximate pressure can be set by use of a vacuum breaker, pump speed, or other means. However, as the filling line speed changes, there is a  large change in the required flow rate. Unless a precision, high capacity vacuum regulator is used, these changes in line speed can have a significant effect on the applied can vacuum. These changes can affect fill accuracy, splashing, or (in the extreme situation) collapse of can wall.

large change in the required flow rate. Unless a precision, high capacity vacuum regulator is used, these changes in line speed can have a significant effect on the applied can vacuum. These changes can affect fill accuracy, splashing, or (in the extreme situation) collapse of can wall.

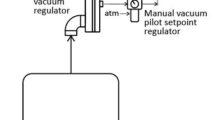

The Equilibar® High Flow Vacuum Valve has been successfully used to control canning and bottle filling vacuum as well as other food packaging vacuum processes. Unlike vacuum breakers, which allow air into the vacuum pump to adjust the vacuum pressure, the Equilibar Vacuum Regulator (EVR) directly controls vacuum pressure by throttling flow between the vacuum supply pump and the process. Refer to the schematic at the left.

The EVR uses an unusually large diaphragm area over a field of multiple orifices to facilitate lightning-fast response to changes in vacuum pressure. Because the EVR is dome-loaded, the desired vacuum setpoint is communicated from a pilot setpoint regulator which can either be a manual or an electro-pneumatic vacuum regulator, depending on the application requirements. In this application, where flow rate can change as the filling operation starts and stops, it may be advisable to use a closed loop electronic or remote sensing pilot regulator which are described in our vacuum pilot setpoint regulator page.

Contact an Equilibar application engineer to learn how your high speed canning or filling operation can benefit from our unique approach to vacuum control.

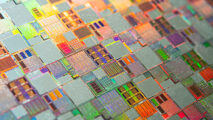

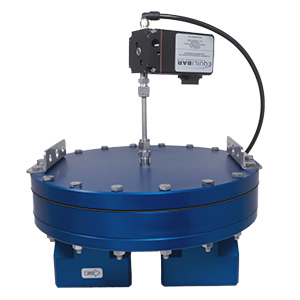

Equilibar’s 2″ Vacuum Control Valve can be used to accurately control vacuum pressures in high speed filling operations

Equilibar Electronic Vacuum Control Valve with electronic pilot setpoint regulator to enable either closed-loop or open-loop computer automation