In reverse osmosis, the water travels from high concentration to low concentration, but because that does not happen naturally, pressure must be applied to the high concentration side of the membrane to force water molecules to the other side. This flow through a reverse osmosis membrane (RO membrane) is how desalination and water purification take place.

In the schematic above, an Equilibar back pressure regulator (BPR) is used at the outlet of the retentate side of an RO membrane to apply pressure for the reverse osmosis process. There is a natural pressure across the RO membrane in the direction of low concentration to high concentration called the osmotic pressure. In order for reverse osmosis to take place, the applied pressure on the retentate side of the RO membrane must be greater than the osmotic pressure.

An Equilibar BPR, with its dome loaded multiple orifice technology, provides precise and consistent pressure for the reverse osmosis process even if the feed water experiences variable flow rates. The required pressure for reverse osmosis to proceed is set by the electro-pneumatic pilot regulator which delivers the exact setpoint in a 1:1 ratio to the dome of the Equilibar BPR.

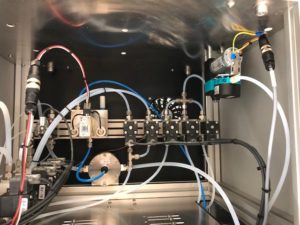

Convergence Industry B.V. uses an Equilibar BPR in their RO System.

Convergence Industry B.V. uses an Equilibar BPR in their RO System.

Membrane Fouling

When microorganisms adhere to the membrane in an irreversible process, it is called RO Membrane Fouling. This prevents the water from flowing properly and the effectiveness of the reverse osmosis process declines. This is a battle that RO scientists face regularly.

At the Massachusetts Institute of Technology, doctoral candidate Emily Tow and other researchers were developing a model to predict membrane fouling in order to find solutions to the problem. Understanding the fouling of the membrane used in RO desalination will make it possible to reduce the overall cost of water treatment and expand access to clean drinking water for people throughout the world. As part of this effort, MIT researchers used an Equilibar back pressure regulator to control the differential pressure across RO membranes, allowing higher resolution in fouling measurement. Read the article here.

For more information about how Equilibar fluid control products can help with your research or manufacturing process, contact an Equilibar application engineer.

GSDH6 General Service Back Pressure Regulator

- Port Sizes:

- 3/4"

- Typical Pressure Ranges:

- 0 - 1000 psi

- 0 - 1500 psi

- Key Applications:

- Reverse Osmosis

- Electrolysis and Electrolyzer pressure control

- Pump Recirculation Loops

- High Viscosity Media