Back pressure regulators (BPRs) are commonly used in membrane separation and membrane filtration processes to carefully control both the permeate pressure and retentate pressure. Depending on the osmotic pressure of the chemistry involved, the differential pressure across the membrane, also called transmembrane pressure or TMP, must be carefully maintained within a narrow range. Many small molecule separations require transmembrane pressures in the range of 1 psi or tens of mbar. Such low pressure control can be a challenge, both in the research environment and in industrial separation applications.

Equilibar’s unique dome-loaded back pressure regulators are ideally suited for these demanding challenges. The frictionless dome-loaded design can easily maintain differential pressures below 1 psig, and it is sensitive to setpoint changes less than 0.01 psi or 1 mbar.

The design of the Equilibar® BPR uses a single sensitive diaphragm of PTFE, Viton FKM or other chemically compatible materials as the only moving part that adjusts instantaneously to keep pressure precisely on target. The regulator bodes can be made from SS316L, Hastelloy, 100% PTFE, or other exotic materials for resistance to strong acids and other chemicals.

The simple design and wide variety of materials for construction allows customers to use Equilibar BPRs in a variety of different demanding filtration applications from tangential flow filtration in biopharmaceutical production to filtration of ultrapure water and chemical feed lines for semiconductor manufacturing.

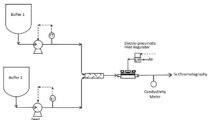

Manual Control Using Differential Air Regulators

There are several ways in which the Equilibar back pressure can be configured to control permeate and retentate pressure in membrane separation applications. In the schematic above, the differential pressure is precisely maintained by a biasing air relay. The dome-loaded back pressure regulators are installed on each stream. The pilot set-point pressure is set explicitly by a simple precision air regulator. The trans-membrane pressure is adjusted by the air biasing relay, which establishes a differential bias from the first pilot pressure.

Electronic Control using High Resolution Regulators

The schematic above shows how electronic pressure regulators can be used to automatically maintain higher resolution control of the trans-membrane pressure. The supervisory controller monitors process pressuring using sensors. PID control algorithms are used to maintain both permeate and retentate pressures at the desired levels. Because both the Equilibar back pressure regulator and the Equilibar QPV electronic pressure regulator have no significant hysteresis or deadband, it is possible to maintain these pressures with high resolution, to 0.1 psid.

Alternate Methods – Gas / Liquid Contacting Membranes with Adjustable U-Tube

The dome-loaded design of the Equilibar offers interesting alternative methods of control for gas/liquid systems. In the schematic above, the trans-membrane pressure is actually maintained by an adjustable liquid-filled manometer. The process gas pressure is used as the basis for the set-point pressure, and the trans-membrane pressure is established by the differential height between the membrane and the surface of the liquid in the U-tube. Because water loses 1 psid with each 27.4″ of elevation rise, the installation of the liquid surface 14 inches below the membrane location would present a transmembrane pressure of 0.5 psig (air greater than liquid).

Differential Pressure Control Using Electronic Pressure Regulators

An electronic pressure regulator can be equipped to control the pressure above or below a pneumatic reference signal. This allows a simplified method for membrane separation differential control that does not require a PID control or external wetted pressure sensors. The electronic command to the dP Modified E/P directly equates to the desired differential pressure.

This “open loop” control can be achieved because of the high resolution of the Equilibar QPV electronic pressure regulator and the low mechanical hysteresis of the Equilibar back pressure regulator.

PTFE back pressure regulator used in continuous pharmaceutical research at Novartis-MIT Center for Continuous Manufacturing.

Watch the video below to see how the Equilibar Back Pressure Regulator works.

How Equilibar Back Pressure Regulator Works