Engineering excellence is the backbone of all we do at Equilibar. We constantly look for ways to enhance and expand our continuous improvement and quality programs.

Here are some of the certifications and guiding standards that we use on a regular basis to provide the highest quality solutions for our customers’ applications.

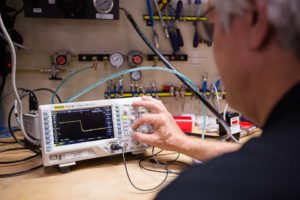

Equilibar’s Quality System is ISO 9001:2015 Certified. The ISO standard was developed by the International Organization for Standardization and establishes a uniform set of measurements for international manufacturers to gauge quality management systems. It provides a strong road map for our continuous improvement efforts and serves as foundation for our quality programs, which involve every aspect of our business. 3A Sanitary – Food grade certification that requires sanitary cleanable and crevice free design. Equilibar does not offer 3A approved products specifically, however, we make BPE biopharmaceutical valves with design features compatible for use in food & beverage. Contact us for more details. ASME B31.3 – ASME Process Piping Design Standard B31.3 contains requirements for piping materials and component design, fabrication, assembly, inspection, and testing. Equilibar design engineers use this standard as the primary technical reference to design products. All new designs are tested by conducting hydrostatic pressure tests in the range of 3-4 times the maximum allowable working pressure. ATEX Directive – Directive 2014/34/EU relating to equipment and protective systems intended for use in potentially explosive atmospheres. A third-party review concluded that Equilibar® back pressure regulators fall under the definition of “simple equipment” as stated in the ATEX Directive Guidelines. For this reason, the equipment is not Ex or CE marked according to the requirements of the ATEX Directive 2014/34/EU. If you are interested in ATEX certified electronic pressure control, please contact an application engineer. BPA Free – Bisphenol A, or BPA, is a colorless organic synthetic compound that is soluble in organic solvents but poorly soluble in water. BPA is a starting material for the synthesis of plastics, primarily certain polycarbonates and epoxy resins, as well as some polysulfones and certain niche materials. Some Equilibar products are BPA free for our clients who require this. BPE – ASME BioPharmacutical Engineering Standard (BPE) lays out recommendations and requirements applicable for the design of equipment used in the bioprocessing, pharmaceutical, and personal-care products industries, as well as other applications with relatively high levels of hygienic requirements. It incorporates current best-practices for enhancing product purity and safety. Equilibar offers FD sanitary back pressure regulators with BPE design features. CE Mark – The letters CE appearing on products signify that products sold in the European Economic Area (EEA) have been assessed to meet high safety, health, and environmental protection requirements. Equilibar sells some electronic pressure regulators that meet CE requirements. Equilibar back pressure regulators that fall under category 0 or SEP (standard engineering practice) are required by the Pressure Equipment Directive (PED) to not carry the CE Mark in order to avoid confusion in the marketplace. Some Equilibar back pressure regulators fall under category 1 for self-certification and application of the CE mark. For conditions that fall under category 2 or higher please contact an Equilibar Engineer to discuss further. CRN Approval– The Canadian Registration Number (CRN) is a number issued by each province or territory in Canada by an authorized safety authority for any boiler, pressure vessel or fitting that operates at a pressure greater than 15 psig (1 bar(g)). CRN number registration requires that the pressure regulator be designed, evaluated and approved per an industry standard. In addition, it requires a review for acceptability by a 3rd party in Canada. Equilibar has a registered CRN in all provinces and territories for a variety of models. Please contact us for more information. EHEDG – European Industry consortium that defines equipment design requirements for cleanability of processes equipment used in hygienic applications. Equilibar is currently working toward products meeting EHEDG requirements, but products are not currently certified. FDA compatible materials – Some materials are “FDA approved for food contact” or other purposes. This is separate from USP Class VI, and more common. Equilibar can ensure some O-ring and diaphragm materials are FDA compatible for those clients who require it. Please contact us to discuss your requirement. Medical Devices or Applications – Equilibar does not have the license to sell back pressure regulators into direct medical applications. However, many medical companies will purchase back pressure regulators for their industrial processes in other applications. NACE MR0175/ISO 15156 – The National Association of Corrosion Engineers and ISO publish the NACE MR0175/ISO 15156 Standard, providing requirements and recommendations for selecting alloys for service in equipment that will be used in oil and gas production in H2S-containing environments. The standards are written to avoid sulfide stress cracking of equipment used in sour service applications. Equilibar engineers are available to speak to you about your application to find a regulator that meets these NACE standards. NIST Traceable Calibration – Our instruments have calibration certificates showing their traceability back to National Institute of Standards and Technology (NIST) measurement standards. These instruments are used to ascertain proper performance of our electronic pressure regulators. PED – The Pressure Equipment Directive (PED) (2014/68/EU) applies to the design, manufacture and conformity assessment of stationary pressure equipment with a maximum allowable pressure greater than 0.5 bar, with the aim of ensuring a high level of safety. Depending on the pressure and internal volume, there as various Classes that define the level of design and CE Marking required. For use with non-hazardous fluids, the majority of our back pressure regulators (BPRs) and valves (BPVs) fall under Class 0 and Class 1 where Standard Engineering Practice is required rather than CE Mark. Equilibar BPRs and BPVs meet Standard Engineering Practice for design by meeting ASME B31.3 standard described above. However, when used with hazardous fluids and higher pressures, higher classifications may be reached for which the CE Mark is required, in which case Equilibar BPRs are not certified. Contact equilibar to discuss what section of the PED your application’s requirements fall into. https://ec.europa.eu/growth/sectors/pressure-gas/pressure-equipment/directive_en TSE Certificate – TSE compliance certificates are a type of CEP (Certificate of Suitability to the European Pharmacopoeia). Transmissible Spongiform Encephalopathies (TSEs) are a family of diseases occurring in man and animals and are characterised by a degeneration of brain tissue giving a sponge-like appearance leading to death. The commonly accepted cause of the TSE diseases is a transmissible agent called a prion (PrPres), which is an abnormal form of a protein. Equilibar actively audits suppliers to provide TSE statements to our clients when requested at the time of order. USP Class VI – United States Pharmacopea standard that defines material suitability for biological pharma processes with an emphasis on absence of extractable contaminates. Equilibar FD Sanitary Series regulators are all stainless steel and have USP Class VI certified wetted polymer / elastomer components. USP Class VI materials that are free from leachable and extractable contaminants are designed for biopharmaceutical use and any other processes where non-leaching materials are required. Vision Statement: To solve the fluid control problems of our clients by better understanding their applications and providing innovative products and application solutions to elegantly meet those needs. Quality Statement: Equilibar actively listens to its clients in order to provide them with solutions that exceed their expectations. Equilibar will continuously improve upon this commitment to our clients by achieving and maintaining a Net Promoter Score (NPS) of 70% or higher. ISO 9001:2015

ADDITIONAL DESIGN STANDARDS and CERTIFICATIONS

EQUILIBAR’S VISION and QUALITY STATEMENTS