In the fine chemicals industry, hydrogenation is commonly performed in a fixed-bed catalytic reactor. An unsaturated hydrocarbon, such as an alkene or alkyne, is reduced in the presence of hydrogen to form a saturated (or more saturated) hydrocarbon.

These reactions are often performed at elevated temperature and pressure to increase the density of the hydrogen and increase the rate of reaction. Reactor pressure control is critical and can be difficult due to aggressive chemicals, high temperature and pressure, and the presence of mixed phase reactants.

The Equilibar® fluid control valve is a dome-loaded back pressure regulator (BPR) which excels in demanding applications such as reactor pressure control. The Equilibar regulator is controlled by a pressure setpoint on its dome using a pilot set-point pressure regulator.

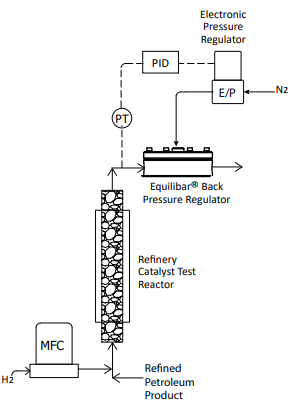

In the schematic shown above, unsaturated hydrocarbon is injected into a reactor via a liquid control valve and hydrogen gas is injected into the reactor using a Mass Flow Controller (MFC). A fixed bed heterogeneous catalysis reactor accelerates the hydrogenation process. The Equilibar back pressure regulator accurately controls the reactor pressure to the setpoint set by the pilot pressure regulator in a 1:1 ratio.

In the schematic above, a manual pilot regulator controls nitrogen pressure to apply the 1:1 setpoint to the BPR. For computer automation applications, a high pressure electronic pressure regulator would command the nitrogen pressure to control the hydrogenation process precisely according to the programmed cycle steps.

Equilibar back pressure regulators are ideal for controlling reactor pressure with their high precision, wide flow range and two-phase flow capability.

An Equilibar LF1 BPR in research of direct synthesis of hydrogen peroxide through O2 hydrogenation. Read about the case study.

Learn more: Hydrogenation in the Vitamins and Fine Chemicals Industry – An Overview by Werner Bonrath et al

Spotlight: Hydrocracking

In the oil and gas industry, removing impurities from petroleum fuels leads to cleaner emissions and improved downstream processing. Hydrodesulfurization (HDS) and hydrodenitrogenation (HDN) are chemical processes that use catalysts to remove sulfur and nitrogen impurities. New EU legislation such as IMO 2020 for marine fuels and Tier 3 for automotive fuels requires substantial reductions of sulfur and nitrogen to reduce their environmental impact.

Hydrocracking is the dual-step process of hydrotreating (removing unwanted sulfur and nitrogen) and hydrogenation (adding hydrogen) of petroleum products to obtain higher quality, lower emission fuel products.

Hydroprocessing, as it is sometimes referred to, is a similar process to the one in the schematic above where hydrogen gas and refined petroleum products are metered separately into a catalytic reactor bed for processing at a specific temperature and pressure. In most cases, the process would be controlled using an electronic pilot regulator. See schematic at right.

Case Study: Benefits of using an Equilibar valve for Hydrocracking catalyst testing

Equilibar’s technology is uniquely well suited for applications involving two-phase flow because it uses a direct sealing diaphragm over multiple orifices to control the pressure drop. A Berlin customer describes these benefits of using an Equilibar BPR to control reactor pressure in hydrocracking catalysis test system:

- The supple diaphragm instantaneously adjusts to the varying Cv requirements of the fluid phases

- The multiple orifice design helps maintain volumetric flow with denser liquid and gas flowing together

- Using a BPR that can handle two-phase pressure control eliminates need for gas-liquid separator

- The compact size and dome-loaded design allows easy placement in an oven to maintain accurate temperature control

- Superior turndown ratio supports a wide range of system pressure setpoints

Contact our engineers to determine which Equilibar back pressure regulator is best suited for your demanding hydrogenation reactor control application. We have many options and years of experience with complex process conditions.

Schematic of hydrocracking reactor pressure control

Case Study : Equilibar back pressure regulator provides benefits in hydrocracking catalyst test systems