Back Pressure Regulators With Positive Displacement Pumps

Back pressure regulators can be used downstream of positive displacement pumps to maintain a stable output flow rate and eliminate pump slip despite widely varying downstream pressure conditions.

Background

Positive displacement pumps are often used to control the flow rate of liquid chemicals throughout industry. Examples of positive displacement pumps are:

- gear pumps

- lobe pumps

- progressive cavity

- piston pumps

- diaphragm pump

- peristaltic pumps

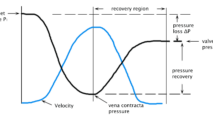

Of these, gear, lobe, and progressive cavity type pumps can experience unwanted slippage with lower viscosity fluids, where a portion of the metered forward flow rate is lost due to back-flow. This slip for a given viscosity is generally proportional to the differential pressure across the pump.

Application Highlight – Liquid Blending

In many blending and injection applications, the pressure downstream of the pump is not constant, but varies according to other process parameters, such as the flow rate of other blended components.

By installing a back pressure regulator downstream of the positive displacement pump, the differential across the pump is stabilized, and therefore the degree of slip is controlled. In this way, the flow rate of the pumping system is stable and independent of system fluctuations downstream of the back pressure regulator.

The schematic at right shows how the flow rate of two chemicals are stabilized when injected into a larger header. In this case, an Equilibar back pressure regulator is controlled manually at a fixed rate using a common air pressure regulator to supply the 1:1 pilot set-point pressure.

Positive Displacement Pump Control for Biopharmaceutical Applications

Sanitary lobe pumps, a type of positive displacement pump, are frequently used in biopharmaceutical and food applications because of their high efficiency, reliability, solids handling ability, CIP capability and sanitary qualities. There are designs available that meet the high standards of EHEDG certification for hygienic food manufacture as well.

One disadvantage of the sanitary lobe pump is that it can experience pump slip or pump runaway when the viscosity of the fluid is low. To eliminate pump slip, biopharmaceutical skid designers install a back pressure regulator to the discharge of the pump. Equilibar FD Sanitary back pressure regulators are an excellent choice for this application and provide the added benefit of pulsation dampening.

Typical biopharmaceutical applications using this setup include chromatography, ultrafiltration and media transfer. Engineers recognize these benefits of the Equilibar FD back pressure regulator:

- Small footprint helps in compact design

- High turn-down ratio permits wide flow ranges

- Precision performance leads to high quality production

- Instantaneous response time enables excellent computer control

- Simple design is easy to install, clean and maintain

- using our BPR as a pump pressure sustaining valve

- using our BPR as a flow control valve

- using our BPR for flow control from a pressurized supply