What is Valve Authority?

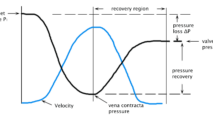

Valve Authority is the ratio of dP across the control valve (dPv) versus the total dP across all system frictional components, including the valve (dPsys). Valve Authority = dPv / dPsys

Engineers who size control valves use the term Valve Authority to avoid selecting a valve that is too large for an application. A common rule of thumb is that traditional control valves must consume at least 25% (if not 50%) of all system dP to have good control and avoid control valve hunting or oscillation issues.

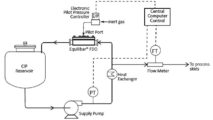

Equilibar engineers have discovered that the 1000:1 turndown of their novel flow control valve is able to sidestep the valve authority limitation and provide stable control of ratios down to 1 or 2%. This capability supports lowered energy consumption in hydronics loops and wide flow rate turndown ratios in dosing and blending . . .up to the limitation of the flow meter.

Watch our video below for a closer look at how the Equilibar control valve operates through a wide operating window, with valve authority down below 5%.

Contact Us

When is Valve Authority an Important consideration?

Using valve authority for control valve sizing is commonly faced in “hydronics” or the control of thermal water circulating loops. In these systems, significant energy is lost by sizing valves to always consume 25% of the pump’s energy. Special purpose valves have been developed to increase control valve stability in these loops, such as Double Regulating Valves and Differential Pressure Control Valves.

Valve Authority is also an issue for valve designers in the process industries, in applications such as dosing or blending. This 25% lower bound limits the flexibility in valve selection, and further limits the ability of process designers to achieve wide flow rate turndown ratios. Having a 10:1 flow rate turndown limitation might be acceptable in a refinery production application, but could be a large limitation in the Research and Development environment where new Coriolis flow meters have the ability to measure flow in a 1000:1 turndown ratio.

How is it possible that Equilibar valves sidestep the limitations of the 25% valve authority rule?

Traditional globe and needle valves have deadband, hysteresis, and delay challenges that limit how fast a PID loop can respond to a flow deviation. Because friction throughout the loop is a function of flow rate, and flow rate is a function of the valve position, trying to steer a fluid system with very low valve authority is like trying to steer a racecar at 200 MPH when the steering wheel has only limited positions.

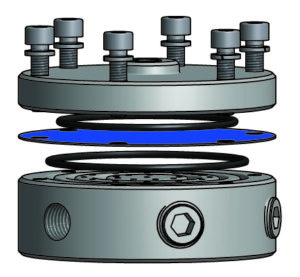

Equilibar flow control valves operate in a totally different manner than globe, needle, or metering valves. The dome-loaded diaphragm is the only moving part and it responds to miniscule pressure changes in milliseconds. This lightning fast mechanical response has nearly zero hysteresis and deadband, meaning that the PID loop has less instability and can easily control to nearly zero valve dP.

The Equilibar control valve opens up access to the higher flow ranges of a hydronics system with its ability to go far below 25% valve authority. This offers the potential to utilize small circulating pumps in hydronic control systems and the potential to dose or blend across much wider ranges in chemical and research processes.

Contact an Equilibar engineer today to discuss how our control valves can improve your flow control application today.

Contact Us