What is Landfill Gas Extraction?

Municipal solid waste (MSW) landfill management includes layering and compounding the waste in a series of layers to promote microbial decomposition – largely through anaerobic digestion. During anaerobic digestion, microbes break down organic waste and release gases like methane, carbon dioxide, and hydrogen sulfide. Section 111 of the Clean Air Act in the US provides legal framework for emissions standards for landfills. As such, larger landfills must find some way of limiting emissions of theses gases to atmosphere. Methane and CO2 are both greenhouse gases and methane may pose a flammability risk. Hydrogen sulfide contributes to acid rain and must be similarly mitigated.

These landfill gases (LFG) are most commonly extracted via gas wells throughout the life of the landfill and even after the landfill is capped. LFG can be collected for 20+ years depending on size and other environmental factors. Vacuum extraction is the most common collection method and Equilibar vacuum regulators can help. Their extreme precision across a wide operating range and ease of automation are all useful in MSW gas collection sites.

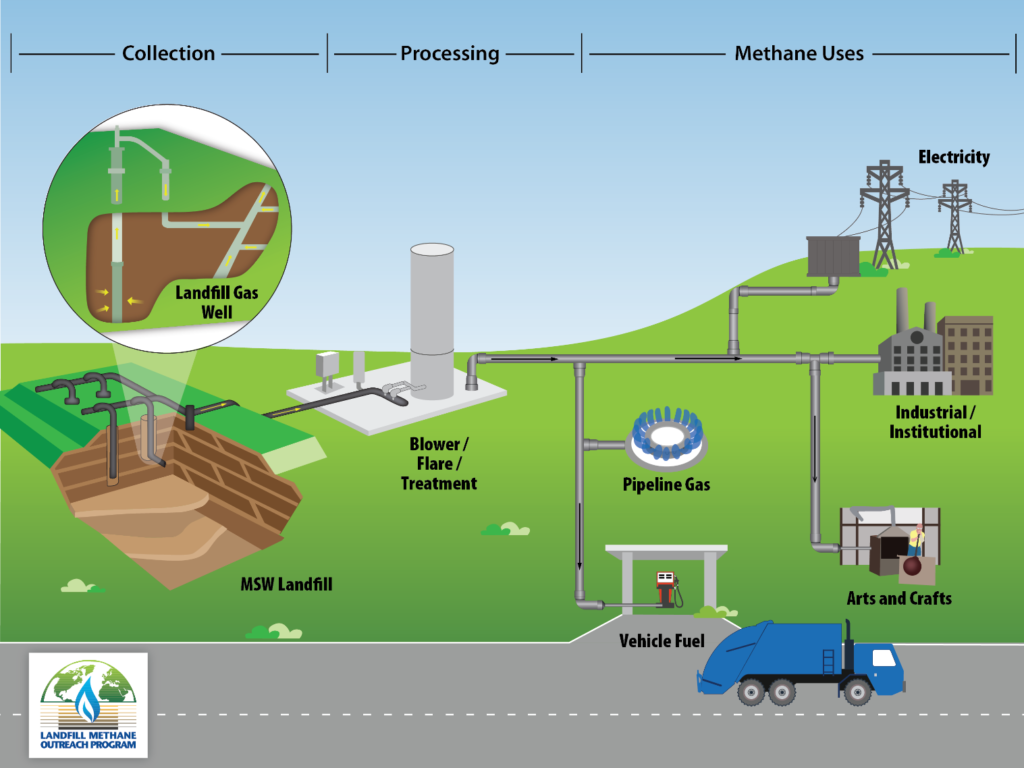

Contact Us to Learn MoreLFG beneficial-use facilities extract and process the methane into renewable natural gas or biomethane. The gas can be combined with pipeline gas or be used to generate electricity. The schematic below from the EPA website illustrates the process.

Source: EPA – Collecting and Treating Landfill Gas https://www.epa.gov/lmop/basic-information-about-landfill-gas

Design considerations for LFG extraction/capture

Active LFG collection commonly uses vacuum extraction methods with vacuum blowers connected to underground vent pipes often called “gas extraction wells” or “gas collection wells.”

Precise Vacuum systems are required

Vacuum systems for landfill gas extraction are controlled very precisely in inches of water column (inWC). Precision control is important because if insufficient vacuum is pulled, then LFG will escape to atmosphere. Conversely, if too much vacuum is pulled at the LFG well, then atmospheric air from will be pulled in along with the LFG. Large fluctuations in vacuum level could also cause condensate build-up or blockages in the system.

Using Variable Frequency Drives for Vacuum control of LFG Wells

Some systems are designed with variable frequency drives (VFD) on the vacuum pump connected to a feedback loop with vacuum pressure control. VFD use is less common in landfill gas extraction because it is often preferable to have a different vacuum level at each well, as the amount of LFG produced and the permeability of the soil varies from well to well, changing the optimum vacuum level needed.

Using manual ball valves to control vacuum at LFG wells

Most commonly, the vacuum level at each well is set via a plastic manually adjustable ball or butterfly valve. Operators will check each well and adjust the valve at the well accordingly. Manual adjustments may introduce system “cross-talk” effect that can cause issues; changing the vacuum level on one well will impact the flow through neighboring wells. When using traditional ball or butterfly control valves, this can lead to a “whack-a-mole” problem, resulting in operators continuously changing the setpoint of each well trying to balance all to the ideal vacuum level. This can make optimizing the vacuum at each well a very lengthy process. Typically, this type of manual adjustment is done rather irregularly, often on a monthly basis, due to the time-consuming nature of this task.

A true vacuum regulator, a valve which instantly and independently adjusts its Cv in response to changes in flow, is needed to avoid this issue.

Advantages of using Equilibar vacuum regulators in LFG extraction

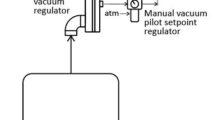

An Equilibar vacuum regulator (EVR) is uniquely suited for the challenging conditions inherent to LFG capture. The EVR can be installed upstream of the vacuum pump to maintain a constant vacuum on the gas collection well regardless of the vacuum source or system pressure. See schematic below.

The EVR is a non-relieving vacuum regulator that throttles flow between the vacuum supply pump and the well system to precisely control the system vacuum at a specific setpoint. It is a dome-loaded pilot operated regulator, so the setpoint is determined by a vacuum pilot regulator on the dome of the EVR. The EVR will maintain vacuum level on a 1:1 ratio with the vacuum setting of the vacuum pilot regulator. It should be noted that while an EVR is often placed downstream of a condensate knockout tank, this is not strictly necessary as all EVRs are able to handle mixed-phase liquid/gas flow.

5 unique advantages Equilibar EVRs offer for LFG capture systems

- Automatic adjustment of Cv – unlike the more commonly used manual ball or butterfly valves, a true vacuum regulator like the Equilibar EVR adjusts its Cv on the fly to keep the setpoint constant.

- Wide operating Cv range – the amount of gas produced by wells can vary wildly, as temperature and other environmental factors influence the rate of gas production from the anaerobic digestion. All Equilibar EVRs have an operating Cv turndown ratio of at least 100:1, with >1000:1 turndown being achievable in most cases. If the amount of flow changes, from changes in gas produced by digestion, permeability of soil, or adjustment of nearby wells, the Equilibar can instantaneously adjust its Cv to compensate and maintain the set vacuum level.

- Ability to handle variable vacuum supply – the vacuum supply provided by a shared header line or blower is not always constant. For a traditional control valve, a change in downstream vacuum supply pressure requires an adjustment of the valve’s % open (and resultant Cv.) The EVR, just like our positive pressure back pressure regulators, automatically adjusts its Cv in response to either fluctuations in flow or downstream pressure while keeping the pressure on its inlet constant.

- Materials for chemical compatibility – the simple design of Equilibar EVRs allows for easy customization to ensure that the valve can handle a variety of other chemicals that may be present in LFG, like hydrogen sulfide. PTFE and Viton seals are commonly used in our EVRs and the body of the valve itself can be made from either metal bar stock like SS316 or polymers like PVC, PTFE, PVDF, or HDPE.

- Reduced maintenance time – the simple design of Equilibar valves, relying only on a flexible diaphragm and set of O-rings, allows them to be rebuilt faster than traditional control valves. (link to rebuild comparison video) Unlike other control valves, there is no recalibration or adjustment needed after installing either.

Learn more about how the EVR works.

Equilibar 2″ EVR can improve landfill gas vacuum extraction systems