Oxygen enriched environments are considered hazardous because it lowers the ignition temperature of materials, making it easier for them to catch fire. Materials that may not burn in normal air may burn more readily in an oxygen-rich environment. While it may seem counterintuitive, a material of concern for use in oxygen enriched environments is stainless steel.

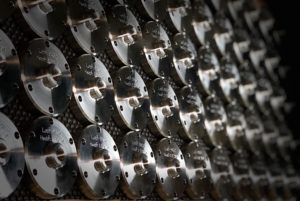

After reviewing application factors, Equilibar often recommends that back pressure regulators for use in oxygen rich applications be made from alternative materials to reduce risk of ignition. Monel, a nickel-copper alloy, is recommended for use in this type of application; In addition to reducing risk of ignition, it has a high resistance to corrosion. The downside is the cost. Brass and nickel-plated brass are both very good for oxygen service and would be less expensive than Monel. Equilibar does not stock many BPRs in these specialty materials, so the delivery time is typically longer than usual.

Diaphragm selection is another consideration. If application conditions are low enough risk to allow stainless steel for the BPR body, Equilibar recommends using a diaphragm material that is difficult to ignite, and which burns with a low heat output if ignited. Flouroelastomers such as PTFE and FKM (Viton®) are good for this. However, if the BPR is made from an alternative material that is difficult to ignite, then the criteria for diaphragm selection is less restrictive.

When a customer orders a BPR from Equilibar for oxygen use, a special cleaning and degreasing process is used at the plant prior to shipping to the customer. During maintenance at the customer site, a thorough cleaning with surfactant or degreaser is recommended as well.

Please contact an Equilibar application engineer to inquire about your oxygen application.

Equilibar engineers make recommendations based on input from the customer but it is the ultimate responsibility of the customer to determine the compatibility of their media with the materials of construction of the back pressure regulator and make final decisions about risk mitigation.

Frequently Asked Questions

What does Equilibar do to “oxygen clean” a regulator?

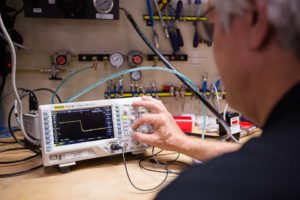

Equilibar has a special degreasing and drying process that is followed prior to testing and shipping a regulator for oxygen use. This special “oxygen cleaning process” should be arranged at time of purchase. Information about the process can be found here.