Some applications require pressure control that crosses from negative to positive pressure relative to atmospheric pressure. While this can appear to be confusing, it is actually quite easy to accomplish.

The Equilibar back pressure regulator works in the same manner for both vacuum and positive pressures. In all situations, the pressure on the inlet port is maintained in a precise one-to-one relationship to the pressure applied to the pilot port. If a vacuum pressure is applied to the pilot port, then the Equilibar back pressure regulator will control that same vacuum pressure on its inlet port. The key is simply finding the right type of pressure regulator that can cross from negative to positive and apply that signal to the pilot port of the back pressure regulator.

Electronic Pressure Control in Absolute Pressure

By using an electronic pressure regulator (EPR) with an internal integrated absolute referenced pressure sensor, it is also very easy to control a process stream from the vacuum to positive pressure range. Equilibar’s QPV ultra resolution EPR has an absolute referenced sensor that natively measures pressure in absolute units. The QPV electronic regulator will supply an absolute pressure signal to the pilot port of the Equilibar back pressure regulator. The resulting electronic control of absolute pressure is useful when computer automating a process.

Schematic #1 – Open Loop Vacuum to Positive Pressure Control

The schematic above shows the simplest, open-loop form of absolute or vacuum through positive control. The electronic pressure regulator is providing an electronic command signal and the accuracy of its internal pressure sensor calibration is relied upon to achieve the desired system pressure. This approach works great when the accuracy tolerance allows. Commonly this open loop control is useful when chemical compatibility, high flow rates, or high temperature abilities of the Equilibar regulator can be used to full advantage.

By selecting an available 0-30 psia sensor, the QPV can easily pilot the dome of the Equilibar back pressure regulator and provide the seamless transition from negative to positive pressure. Click here for more details about the QPV electronic pressure regulator.

Schematic #2 – Closed Loop Vacuum to Positive Pressure Control

This schematic above shows how an externally mounted pressure transmitter and a PLC or PID (proportional integral derivative) controller can be used in situations where higher accuracy is required. The pressure transmitter signal is compared to the desired vacuum or absolute pressure setpoint and this information is used by the controller to modify the command signal to the electronic pressure regulator.

Manual Control

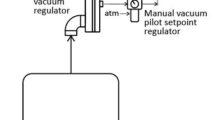

There are several manual vacuum regulators that can control from negative to positive gauge pressures. These require both a positive and vacuum supply pressure, and typically measure referenced to atmospheric pressure. The Bellofram Type 77 vacuum regulator, shown at right, can be used to conveniently pilot the Equilibar back pressure regulator through the negative to positive range (relative to atmosphere).

By connecting a manual to positive pressure regulator to the Equilibar back pressure regulator’s dome, it is possible to control a larger process stream in this same range. For most processes, a positive pressure source must be available upstream of the Equilibar back pressure regulator, and a vacuum supply (pump) must be available downstream of the back pressure regulator.

Applications

Vacuum through positive pressure applications that are referenced to local atmosphere (gauge referenced) include evacuation and fill. Evacuation and fill is often used when an inert gas must be back filled into a vessel. This occurs when multi pane windows are filled with Argon gas or when food packages have oxygen-containing air vacuumed out and replaced with an inert mixture.

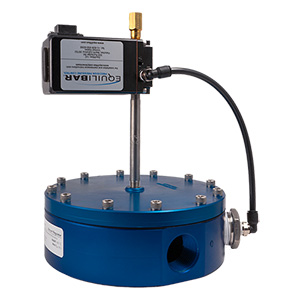

Equilibar EVR Series precision vacuum regulator

The Equilibar® precision vacuum regulating valve (blue) can be be coupled with an absolute range electronic pressure regulator (black) to form a vacuum-to-positive pressure control solution.

Equilibar® QPV electronic pressure regulator