Preventing Solvent Flashing in Polymer Production

After the mixing stage, the polymer solution is often sent to a flash tank where pressure is reduced to just above the vapor pressure so that the volatile organic compounds (VOCs) can evaporate and be removed from the polymer. It is important to keep the polymer at a constant temperature and at a pressure above the vapor pressure as it travels to the flash tank. Sometimes the mixture is sent through a heat exchanger to the flash chamber.

In the schematic above, an Equilibar back pressure regulator (BPR) is positioned at the outlet of the heat exchanger to precisely control polymer pressure in the heat exchanger. The Equilibar BPR maintains the pressure dictated by the manual pilot regulator, which can be set to a pressure above the vapor pressure. An Equilibar BPR can be specified for the unique conditions of polymer processing at high temperatures, pressures and viscosity. Contact an application engineer for more information.

Polymer Devolatilization

The removal of volatile substances from polymers, which is called devolatilization, is an important operation in polymer manufacture. Environmental regulations require lower residual organic volatiles in plastic materials, creating a need for efficient devolatilization in polymer production.

In general, polymer devolatilization starts with the polymer flowing through a heat exchanger then into a vacuum flash chamber where the volatile organic compounds (VOCs) are separated from the polymer. The devolatilization chamber is similar to a vacuum distillation column where the VOCs exit through the vacuum line at the top of the chamber and the polymer is discharged from the bottom section of the devolatilization chamber. See figure below for example of how an Equilibar vacuum regulator may be used to precisely control vacuum in a devolatilization chamber.

Contact an Equilibar application engineer to discuss your system design today.

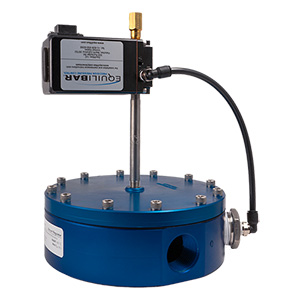

Equilibar BD Industrial Series back pressure regulator in Stainless Steel

Equilibar EVR Series precision vacuum regulator