Why is bioreactor headspace pressure important?

Bioreactor headspace pressure fluctuation can be detrimental to the health of cells in culture, and therefore affect titer.

- Irregular pressure fluctuation is an abnormal state, not natural to a cell’s normal living environment.

- Fluctuating pressure can affect the size of sparge gas bubbles as they rise in the broth and impinge upon cells.

How can an Equilibar Back Pressure Regulator help control bioreactor headspace?

The bioreactor environment is complex. As sparging gases are introduced during the process, they create fluctuations in temperature, pressure or level. In order to maintain healthy cells, the pressure balance in the system must be maintained.

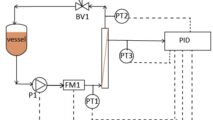

For instance, in the schematic example below, sparging gases are introduced to the broth from below and an Equilibar back pressure regulator (BPR) is maintaining the headspace pressure in the bioreactor. As fluctuations in temperature and level change the pressure balance in the system, the Equilibar BPR reacts instantaneously without hysteresis to maintain accurate pressure. The unique Equilibar design allows the BPR to respond quickly even at the very low setpoint requirements for this application.

Equilibar sanitary BPR controls a bioreactor headspace

Equilibar has two families of sanitary BPRs: The Stainless Steel FDO Series, and the Single Use SDO Series. Whether you have a single use, stainless steel or hybrid system, Equilibar has the BPR for your application.

In Stainless Bioreactors, an Equilibar FDO Back Pressure Regulator will control pressure much more accurately than traditional globe style back pressure regulators, without the slight pressure overshoot that can occur before setpoint is reached.

In Single Use Bioreactors, solenoid valves typically control pressure by pulsing open and closed causing periodic pressure fluctuation. An Equilibar SDO back pressure regulator precisely regulates head space pressure without any fluctuation.

The Equilibar BPR is dome-loaded with pilot operation and uses a supple diaphragm over a field of multiple orifices to create a pressure balance. The patented design results in a very sensitive BPR capable of maintaining stable pressure at extremely low ranges down to inWC/mbar pressures. Compared to traditional spring solutions, they offer ultra-low pressure control without exhibiting over-pressure behavior.

Contact an Equilibar application engineer for more information.

Equilibar FDO6 Sanitary back pressure regulator

Equilibar SDO6 Single Use back pressure regulator

Request a Quote Download Brochure

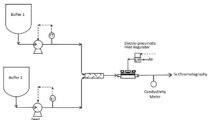

While this schematic does not have one, bioreactors may have a perfusion filtration system incorporated to increase cell life and yield.