The petroleum industry has special requirements for back pressure regulators (BPRs) used in conducting core analysis of rock samples (core plugs). In conventional core analysis, samples are analyzed to determine hydrocarbon content that can be evolved at different temperatures and time while maintaining a pressure consistent with the reservoir’s overburden pressure. In core flooding experiments, the rock’s permeability to gas, oil, and brine is measured.

Back pressure regulators are a key component of many core analysis applications. While some core analysis experiments use inert gas flow through the sample to transport the hydrocarbons, many other core analysis applications require that the sample reactor maintain a constant pressure under no-flow conditions. For example, a rock sample may evolve no gases or hydrocarbons during the early part of a temperature ramp, but later evolve significant flows of condensable hydrocarbon gases as the temperature ramps up.

Core Flooding Example

A back pressure regulator is often located downstream of the core sample reactor to maintain the “overburden” pressure during core flooding. The ideal BPR can hold the reactor pressure at a very stable pressure even as the flow rates vary from true zero flow up to high flow rates (typically tens or hundreds of ml/min).

Unfortunately, most existing back pressure regulators either cannot hold stable pressure under zero-flow conditions, or they cannot provide stable inlet pressures as flow is initiated and increased.

Equilibar’s Zero-Flow Back Pressure Regulator

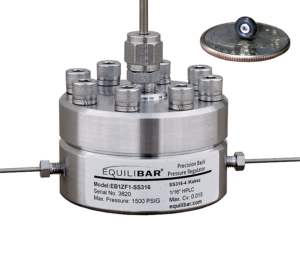

In 2011 Equilibar released a new type of BPR that is specifically designed to address the challenging requirements of the reservoir testing industry. The ZF (“Zero Flow”) Series regulators hold inlet pressures stable within about 0.5% from true bubble-free zero flow, up to the range of 1 liter/minute.

The ZF1 regulator has been proven to address critically challenging and previously impossible applications in core analysis and other research applications requiring micro-flow pressure control.

A soft-seal elastomeric O-ring is used to accomplish the ultra-tight closure in the ZF. The ZF is available SS316 (standard) or other alloys such as Hastelloy C. Although standard fittings are NPT, available low dead-volume styles include HPLC (Valco-style) or Autoclave Engineer style.

Watch the video below of how the Equilibar Back Pressure Regulator controls nano flow rates.

Slim-Tube Testing

Another key use of Equilibar back pressure regulators in the arena of reservoir testing is slim-tube testing. As explained in Schlumberger’s Glossary, this test is used to determine the minimum miscibility pressure (MMP) or minimum miscibility concentration (MMC) of an injection solvents in selected reservoir oil. Fluids are injected into long coil of tubing packed with sand; the back pressure regulator is key to maintaining the coil pressure at the specified values.

The high precision and two-phase tolerance of the Equilibar BPR can improve the performance of the slim-tube test apparatus. Contact our engineers to discuss how an Equilibar BPR can be used at pressures up to 10,000 psig in your process.

Follow these links to learn more about the unique capabilities of Equilibar patented back pressure regulators and about how they work:

- high temperature capabilities

- Low dead-volume regulators

- severe chemistry compatibility

- high pressure capabilities.

- How Equilibar back pressure regulator technology works

Contact an Equilibar application engineer to discuss your unique application.

Equilibar ZF back pressure regulator specifically designed for nano-flows in reservoir core testing.