The LSVAC process is used for high-volume complex air melt castings such as lightweight or hollow parts. Several parts are often cast at the same time using one main vacuum supply to draw vacuum on several castings.

In the LSVAC process, thin-walled resin molds are backed with loose sand inside a vacuum chamber, and then lowered into the melt furnace. Vacuum is applied to the mold in the vacuum chamber to draw the metal up into the mold cavities. After the casting has solidified, the vacuum is released.

In order to have consistently high yield in this process, it is critical to set up the vacuum system with precisely controlled and reproducible vacuum levels. The most reliable control scheme for this application is to have a vacuum regulator controlled through a PLC in a closed loop remote sensing configuration.

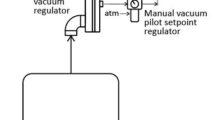

Schematic of loose sand vacuum assisted casting (LSVAC) using Equilibar vacuum regulator

Equilibar has a precise and reliable system for this application. The Equilibar Vacuum Regulator (EVR) with an Equilibar QPV1 electronic vacuum pilot regulator can be configured with an existing PLC or DCS system for closed loop remote sensing control of a vacuum system. The schematic above shows a general layout for this configuration.

Because of their unique multiple orifice design, Equilibar vacuum regulators respond instantaneously to changes in vacuum supply or setpoint pressure. When combined with an electro-pneumatic vacuum pilot regulator, the EVR delivers smooth automated computer control much faster than most other vacuum valves. When the vacuum load changes as the molten metal is drawn into the mold, the Equilibar vacuum regulator can compensate quickly to provide continuous vacuum pressure.

Equilibar vacuum regulators are available in 316SS, anodized aluminum or PVC, with O-rings and diaphragm materials to meet the needs of the most challenging vacuum environments. Certain designs can withstand process applications with ultrapure and aggressive chemical fumes and moisture. Options are also available for high temperature performance that may be experienced in vacuum casting.

Contact an Equilibar application engineer for information about how Equilibar products can be used for your vacuum process.

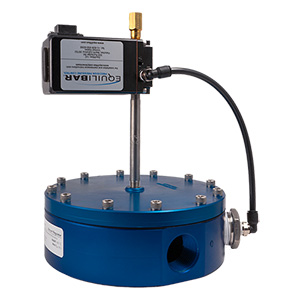

Stainless Steel Equilibar EVR-GSD6 with manual pilot controller

Anodized Aluminum Equilibar EVR-GSD8 with a QPV electronic pilot controller