Challenges in chromatography system design for biopharma processing

In bioprocessing, chromatography skids must be designed to handle a wide variety of fluids from multiple sources to execute different chromatography steps in the manufacturing process. Delicate resins require tight control of pressure and flow parameters. Processing challenges include:

- Delivering fluids at precise flow rates across a wide range of flow rates, including very low flow, as required by the various process steps.

- Eliminating pulsations that often arise from the use of diaphragm pumps, which can harm the resin or create “channeling” that results in inefficient processing.

- Providing consistent back pressure to prevent bubble formation, which could lead to process disruptions downstream.

How pulsation dampening works

Upstream pulsation dampening or damping is a natural behavior of the Equilibar valve. The upper diaphragm naturally responds to slugs of fluid moving through the valve, keeping upstream pressure constant. The ultra-wide Cv range of the Equilibar valve allows it to keep up with positive displacement pumps and diaphragm pumps to maintain consistent upstream pressure throughout the run.

For downstream pulsation dampening, the Equilibar FD Series back pressure regulator comes with passive dampening inserts to minimize pressure pulsations downstream.

In extreme cases, the Equilibar FDO sanitary back pressure regulator can be equipped with active dampening technology in a redesigned bottom cap to accommodate processes with excessive downstream pressure fluctuations due to process equipment such as pumps. This configuration offers the same precision control across a wide range of flow rates as the standard design, with the benefits of improved downstream pulsation damping all in one valve. It does involve a more complex installation setup. Please contact Equilibar to learn if this is a good fit for your process.

Contact Us to Learn More Download FD Active Damping Addendum

Below is a case study with some early feedback. For information about the dampening behavior of our standard FD product line, visit this web page.

Case Study: active damping technology improves performance in biopharma manufacturing

Equilibar engineers worked with a biopharmaceutical end-user to provide an FDO BPR with active dampener to solve two issues. In addition to stabilizing the diaphragm pump outlet upstream of the FDO, this unique BPR has an actively adjusting pulsation dampener for the downstream chromatography process.

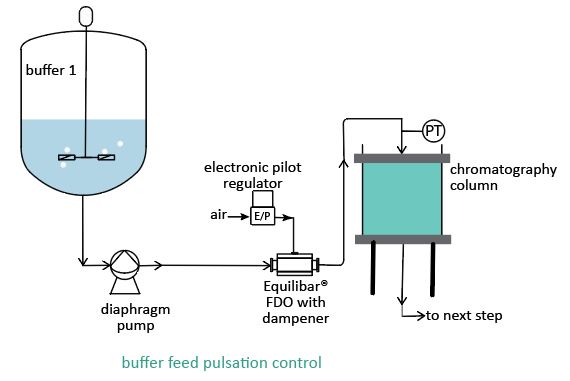

In this case study, a designer of purification platforms was building a system to deliver buffer & Water-For-Injection (WFI) sources to chromatography columns and other filtration processes via diaphragm pump. The design included an Equilibar sanitary back pressure regulator (BPR) downstream of the diaphragm pump. BPRs are often used at the outlet of diaphragm pumps to optimize operation by keeping pressure stable and ensuring that the check valves inside the pump are engaged.

While testing the new delivery system at a large biopharmaceutical customer account, engineers noticed instruments were showing pressure pulsations immediately upstream of the chromatography column and downstream of the Equilibar BPR during several steps of the process. They were concerned that the pressure fluctuations would disrupt the chromatography process and trip pressure sensitive alarms that stop the manufacturing process. See Schematic below.

Equilibar FDO Sanitary BPR with active pulsation dampener in chromatography skid

Solution – Equilibar back pressure regulator with active pulsation dampening

Many sanitary systems are extremely sensitive to pressure pulsations. In response, Equilibar designed a unique sanitary BPR with active pulsation dampener to be used in these circumstances. It is still in development.

Incredible results – active pulsation dampener reduces pulsations by 99%

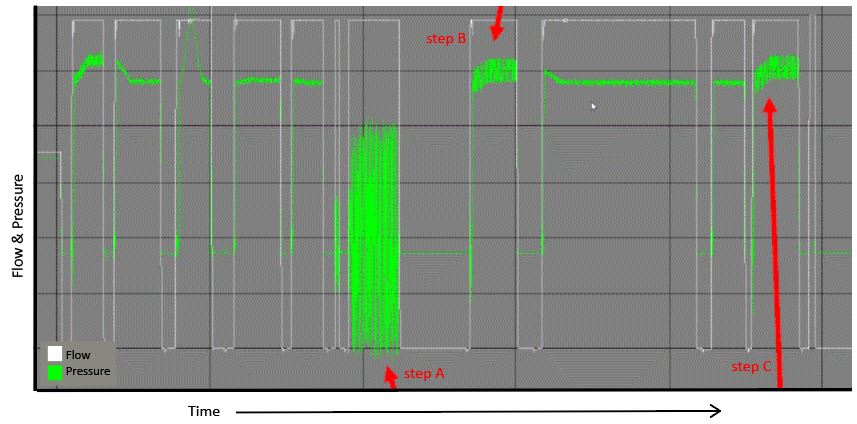

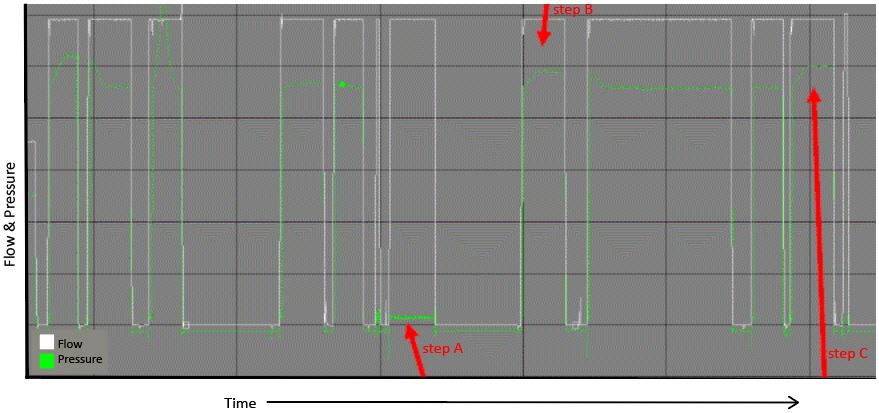

The process engineer had recorded the pressure during the chromatography steps with the standard BPR installed and compared that to the pressure readings with the active dampening BPR installed. Figures 2 and 3 below show the comparison. The white lines show flow rate and the green lines show pressure. Use of the active damping BPR resulted in excellent results with an extraordinary decrease in pulsations. The engineers at the customer site report they are happy with the improved reliability of their process.

Figure 2: Flow and pressure measurements using standard BPR

Figure 3: Flow and pressure measurements using Equilibar active dampening technology

About the Equilibar Sanitary Back Pressure Regulator

Equilibar FDO sanitary back pressure regulators come standard with passive pulsation dampening. If you are interested in active dampening model, please contact Equilibar.

FD Series Sanitary back pressure regulator designed for biopharma processing

What is a pulsation dampener?

Pulsation dampeners stabilize pressure and flow rate fluctuations sometimes caused by the mechanical action of a dosing pump. They are placed downstream of a pump to alleviate pressure fluctuations.

Contact Equilibar