Altitude Simulation Regulator

Altitude Simulation Chamber precision to +/- 30 feet

Altitude test chambers are used by many industries to simulate conditions of varying atmospheric pressure, temperature, and humidity. For example, automotive performance and emissions must be documented for various altitudes. High altitude simulation chambers are also required to test pilot masks and other cockpit equipment. Recently, athletes have begun training in altitude chambers simulating the low-oxygen conditions found in mountainous regions to build stronger blood oxygen capacity.

For small to medium chambers, manual vacuum regulators with manual adjustment knobs have been used successfully for decades. However, these units are typically available in limited sizes, usually 1/2″ or smaller. For larger sizes, flow control valves have traditionally been used with relatively slower acting PID control loops; however, for these larger chambers, achieving good precision is often difficult. Pressure control to +/- 500 feet in altitude has been considered typical.

For testing human exhalation in high altitude chambers, for example, there is a real challenge from the massive volumetric expansion of the air flow from exhalation into the low pressure chamber. By way of illustration, a human exhalation at 30 standard Liter/minute at pressurized mask pressure would explode into 600 actual liters/minutes at the low absolute pressure found at high altitude. Small 1/2″ pressure regulators are unable to precisely handle flow rates in the larger volume systems.

While large PID-controlled flow control valves are able to handle extremely large flow rates, they are unable to adjust to sudden flow changes, such as from a normal exhalation cycle.

All of the factors contribute to the relative imprecision that operators of altitude simulation chambers have traditionally coped with.

Greatly improved precision at high flow rates

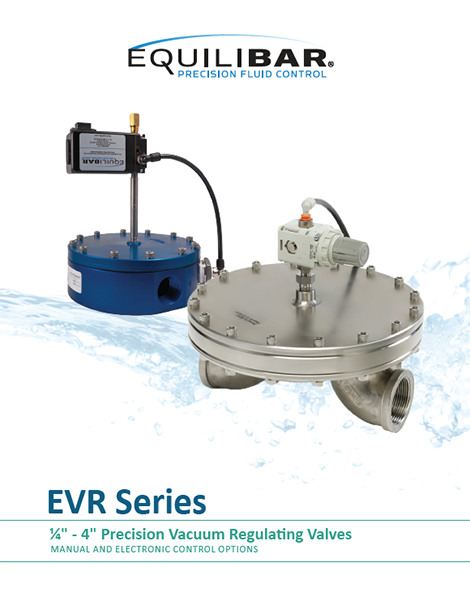

Equilibar has recently demonstrated a high precision altitude simulation regulator that dramatically increases the accuracy and stability of large test chambers. The dome-loaded vacuum regulator uses a precision set-point signal from a high speed electronic pressure regulator. The direct-sealing diaphragm regulator translates the small pressure signal from the electronic pressure regulator 1:1 to the much larger air flow coming from the test chamber.

Results in a large high altitude simulation chamber operated by a large military agency reveal an incredible precision of +/- 10 to 30 feet of altitude resolution, even with varying flow rates in open-loop control. Users may use a closed-loop feedback mechanism for further resolution if needed.

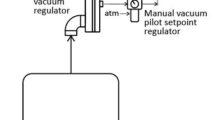

Altitude Simulation Chamber Schematic

In the schematic above, a vacuum pump is throttled by the Equilibar precision vacuum regulator as part of a computer control system. The supervisory computer or PLC contains a PID control loop, which makes fine adjustments as necessary to the set-point command to the I/P (electronic pressure regulator) until the altimeter (PT) closes to its desired setting. These are unlike PID flow control valves in that the response of the Equilibar device to sudden changes in flow is nearly instantaneous (few milli-seconds), compared with several seconds for a typical flow control valve loop. The PID is used only as an optional method to enhance precision and is not required for the basic functionality of the system.

If rapid decreases in altitude are required, additional in-flow of air (or gas) is provided through a small solenoid valve. The pressure is maintained in tight control at all times by the larger capacity of the Equilibar vacuum regulator.

The patented Equilibar back pressure regulator technology is unique in its ability to translate this precision into high vacuum flow streams. The use of thin, supple diaphragms results in pressure control with zero hysteresis and sensitivity to pressure changes well less than 1 mBar.

The Equilibar QPV electronic pressure regulator is ideal for producing the 1:1 pressure signal for the vacuum regulator due to its lack of hysteresis and its extraordinarily high resolution. Together, the QPV and precision vacuum regulator complement each other to deliver resolution as high as +/- 10 feet (+/- 3 meters).

The QPV is available in either gauge or absolute pressure versions. If the user’s control system already references a high quality altimeter, the use of an absolute pressure sensor is not necessary. However, for simpler installations, the use of an absolute pressure sensor can easily eliminate the effect of changes in barometric pressure on the chamber’s altitude.

Learn more about Equilibar’s vacuum regulators.

Contact our engineers to discuss your unique application.