What is a fuel cell or electrolyzer test stand?

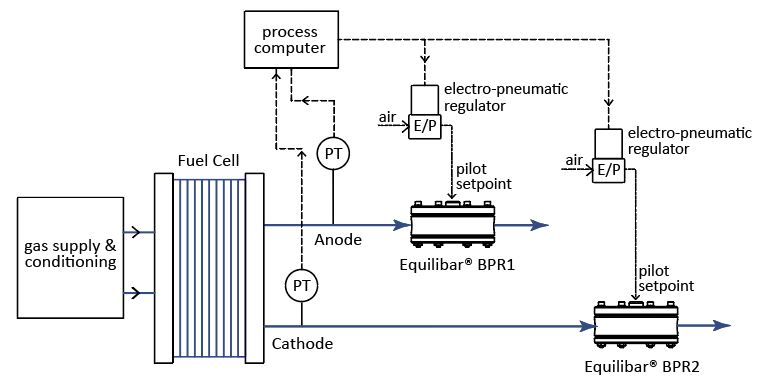

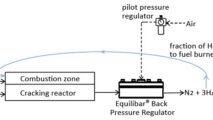

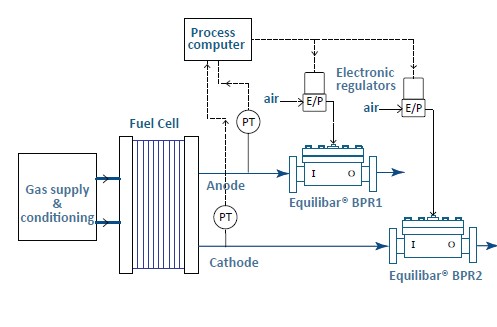

Fuel cell test stands measure the power generated from Hydrogen Fuel Cells at varying pressure and flow rates. Electrolyzer test stands operate with a very similar layout, testing the output of hydrogen and oxygen as variable power is delivered to the cell. In both cases, flow rates during testing vary widely and the reaction products are mixed phase fluids. Equilibar® back pressure regulators are used in both test systems to control the outlet pressures of the anode and cathode of the cell while it is being performance tested.

Key performance characteristics for fuel cell and electrolyzer test stand pressure control

The Equilibar® precision back pressure regulator (BPR) is the perfect fit for pressure control in fuel cell and electrolyzer testing systems. In particular, hydrogen test stands benefit from

- The high sensitivity of the Equilibar BPR in the low to mid pressure ranges that is lacking in most competitive products.

- The unmatched 1000:1 flow turn-down ratio and wide control range of the Equilibar BPR

- The capacity of the Equilibar BPR to control multiphase fluids easily and with extreme precision due to its unique multi orifice design.

- The dome-loaded control of the Equilibar BPR, allowing it to pair with an electronic controller for superior automation.

Low Flow Control

Incredible 1000:1 Flow Rate Turn-down Ratio

Equilibar’s fuel cell and electrolyzer testing valves are specifically designed in response to the demanding flow rate requirements of the hydrogen testing industry. These regulators can provide stable cell pressures through ultra wide flow rate ranges required for rigorous test protocols. Gas flow rate control is possible down to below 1 ml/minute.

Equilibar BPRs control the outlet pressures of the anode and cathode of the cell while it is being performance tested.

Ease of Computer Automation

The Equilibar BPR operates using a pilot regulator on its dome to provide a setpoint. The dome loaded design is sensitive to changes in an Electro-Pneumatic Regulator (EPR) setpoint as small as 0.001 psig, giving a process computer unprecedented control of gas system pressures. While most fuel cell and electrolyzer testing systems use closed-loop PID feedback on the cell outlet pressure sensor, the incredible precision of the Equilibar BPR allows for full system control using an EPR with open-loop control or simply using a manual pressure regulator as a pilot setpoint regulator.

Ability to Control Multi-phase Fluids

The unique multi-orifice design of Equilibar BPR allows for stable pressure control with mixed phase (liquid-gas) flow or varying pressures on the outlet of the BPR. Multi-phase flow in fuel cell and electrolyzer testing systems occurs when gas and condensation are mixed. Traditional valves and back pressure regulators may have a single annular valve seat, often very small. Slugs of liquid and gas mixture in the small throat of these valves may cause a disruption in the stability of the upstream process pressure. The Equilibar BPR with it multiple orifices handles the liquid/gas mixture smoothly.

Contact an Application Engineer to help select the perfect back pressure regulator for your test stand application.

Equilibar IC Series back pressure regulator with electronic pilot for automated fuel cell testing

Customer Case Study – Improving catalysts for automotive fuel cells

Researchers at Charles University in Prague, Czech Republic, have successfully used an Equilibar® Back Pressure Regulator combined with a QPV electronic pressure regulator to provide precise control of fuel cell anode and cathode pressure across a wide range of test conditions. The research is part of vital international efforts to develop improved environmental catalysts for automotive fuel cells. At Charles University, fuel cell research is working to develop improved catalysts with the goal of lowering noble metal content, which would directly lower the cost of the power supply while also using more environmentally friendly materials. Read a detailed account in the link to the right.

Read Case Study

The Fuel Cell and Hydrogen Energy Association is dedicated to the commercialization of fuel cells and hydrogen energy technologies.

Fuel Cell Testing case study from Charles University in Prague

IC Series valves are designed with fuel cell and electrolyzer systems in mind. They are built for test systems with higher flow ranges

IC16 Industrial Back Pressure Regulator

- Port Sizes:

- 2"

- Typical Pressure Ranges:

- 0 - 10 in WC

- 0 - 28 in WC

- 0 - 0.7 psi

- 0 - 1.4 psi

- 0 - 2 psi

- 0 - 3 psi

- 0 - 5 psi

- 0 - 10 psi

- 0 - 20 psi

- 0 - 30 psi

- 0 - 60 psi

- 0 - 100 psi

- 0 - 150 psi

- 0 - 175 psi

- 0 - 200 psi

- 0 - 250 psi

- 0 - 300 psi

- Key Applications:

An Equilibar GS series regulator is a good solution for your lower flow range fuel cell testing

GSD4 General Service Back Pressure Regulator

- Port Sizes:

- 1/2"

- Typical Pressure Ranges:

- 0 - 1 in WC

- 0 - 10 in WC

- 0 - 2 psi

- 0 - 5 psi

- 0 - 10 psi

- 0 - 20 psi

- 0 - 30 psi

- 0 - 60 psi

- 0 - 100 psi

- 0 - 150 psi

- 0 - 200 psi

- 0 - 250 psi

- 0 - 300 psi

- Key Applications:

Watch the video below of how the Equilibar Back Pressure Regulator works.