How Equilibar FDO valves help with liquid ingredient blending in sanitary applications

- Careful blending of two liquid ingredients in food production or in personal care products requires precise pressure control at the mixing site.

- Equilibar FD Series back pressure regulator is capable of controlling pressure at extremely low flow rates, allowing a more exact mixture of ingredients during product blending.

- Food and personal care products require sanitary processing equipment designed with easy cleaning for reduced contamination. Equilibar FD valves have a crevice-free design and meet ASME BPE standards. They can be used in processes requiring 3A or BPE.

- FD series valves are available in small sizes down to 1/4″ port size for precise dosing of ingredients.

- Viscosity is a big challenge in liquid blending. The FD multi-orifice valves control very low and highly viscous fluids with ease.

Application Spotlight: Precision dosing of perfumes and dyes into liquid soaps

Many manufacturers of personal care products need to precisely control the amount of perfume, dye, or active ingredient injected into a processing line. Performance of positive displacement pumps used for this can be improved, especially in low viscosity applications, by the addition of a precision back pressure regulator at the outlet.

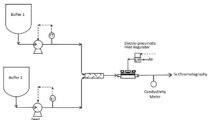

In the schematic below, FD Series BPRs are positioned at the outlet of delivery pumps adding ingredients to a main product line. With its unique multiple orifice design, the FD regulator is capable of controlling pressure at extremely low flow rates, allowing a more exact mixture of ingredients during product blending. Additionally, the Equilibar FD regulator acts as an isolator for header pressure fluctuations as blended product flows through the main header. This keeps downstream fluctuations from adversely impacting upstream flow control equipment.

FD BPRs help maintain back pressure on positive displacement pumps for improved dosing of dyes and perfumes

Application Spotlight: Inline mixing of confectionery ingredients with differing pressures

Liquid ingredient mixing for foods and confections can be challenging, particularly with liquids of dissimilar viscosities and pressures. If the two process lines meet at the mixing point with a large pressure differential, the liquid proportions could be incorrect, degrading product quality and consistency. This type of mixing challenge is seen in food & beverage as well as chocolate & confectionery production. Equilibar FD valves can meet the challenge.

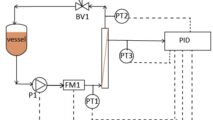

The schematic below shows how Ingredient A, getting delivered at a high pressure, can be mixed with Ingredient B at a low pressure. This might be a mixture of syrup and colorant, for example. In this configuration, low pressure Ingredient B is set up in a recirculation loop with an Equilibar FDO in closed loop control. Higher pressure Ingredient A is being delivered directly to the mixer. At the mixer inlet, PT1 and PT2 measure the pressure and send the information to the PID controller. The PID controller adjusts the signal to the electro-pneumatic regulator setting the pressure setpoint for the Equilibar FDO which maintains the pressure of Ingredient B equal to that of Ingredient A. By maintaining equal pressure at the mixer, the quality of the final product is reproducible and on target each time.

Equilibar FDO regulators with their multiple orifices, dome-loaded control, and supple diaphragm allow them to operate with tight tolerances when controlling pressure around a mixing point which would otherwise have uneven pressures. They respond immediately to pressure fluctuations and setpoint changes, and can handle the challenges of viscous fluid ingredients.

Contact an application engineer for help selecting an Equilibar valve for your sanitary application.

An FD Series back pressure regulator is capable of controlling pressure at extremely low flow rates, allowing a more exact mixture of ingredients during product blending.

Download FD Brochure Contact Us