Push-through flow can exacerbate several issues within bioprocessing operations:

- Deviations in the intended concentration of solutions, affecting the efficacy and safety of the final product.

- Imprecise dosing and timing, which can be critical for product quality

- Unchecked flow may result in the unnecessary waste of high-value media and buffers, increasing production costs.

How to Prevent pump push-through flow

A reliable method to counter this challenge is to place a back pressure regulator (BPR) at the outlet of the pump. A BPR maintains consistent pressure upstream of the pump, ensuring that flow rates remain controlled despite the head pressure on the pump inlet. By providing back pressure slightly above the head pressure, the BPR ensures that the pressure within the delivery system is maintained, effectively eliminating the uncontrolled push-through flow.

Why is Equilibar FDO sanitary BPR the ideal solution for eliminating push-through flow?

Equilibar FDO sanitary BPRs are designed and built using BPE standards for bioprocessing applications where precision and cleanability are paramount. Their unique multi-orifice dome-loaded design with supple diaphragm results in instantaneous control when system pressure fluctuates. The dome setpoint can be maintained either manually or electronically depending on the system needs. Their ability to maintain stable pressures even at low flow conditions makes them ideal for controlling push-through flow in bioprocessing settings.

- Set the FDO setpoint slightly greater than the incoming pump suction pressure to eliminate push-through flow.

- When the pump is off, the pressure setpoint of the FDO will prevent any flow through the system.

- When the pump is set at low flow, the FDO will maintain enough back pressure to allow accurate low dosing flow through the process.

- The FDO is capable of handling a very wide flow range, making it easy to control any flow range generated by the pump.

Equilibar® FD Series back pressure regulators are known for their precision and reliability. Their simple construction allows for easy cleaning and maintenance, making them particularly suitable for sanitary environments.

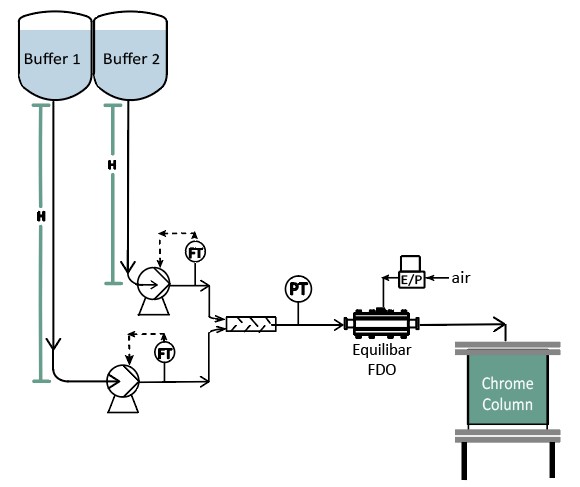

Application Highlight: FDO in buffer delivery system eliminates push-through flow

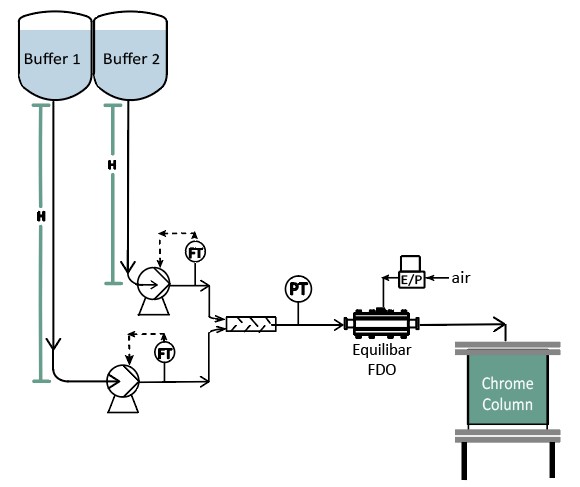

In the example below, an Equilibar FDO sanitary back pressure regulator is positioned after the buffer delivery pumps and inline mixer to control pressure in the diaphragm pumps. In this system, the buffer solutions are stationed at a higher elevation than the pumps, creating a head pressure which can push unwanted fluid through the system. The Equilibar FDO is set up to provide sufficient back pressure to counterbalance the head pressure, resulting in precise and smooth product delivery to the chromatography column downstream.

An Equilibar FDO sanitary BPR is positioned downstream of the buffer delivery pumps to counterbalance upstream head pressure and prevent push-through flow

How else does the Equilibar FDO help in bioprocess delivery systems?

Beyond pump push-through issues, the FDO valve can dampen flow pulsations which often arise with the use of positive displacement pumps in sanitary processing. Damping pulsations will stabilize pump flow performance, improve flow meter accuracy, and maintain smooth operations downstream.

Regulating system pressure also helps protect downstream equipment from pressure-related damage, extending the lifespan of the system components.

Ultimately, addressing pump push-through flow is essential for ensuring high-quality outcomes in bioprocessing. By utilizing an FDO regulator in delivery systems, pharma engineers can improve product quality and reduce waste.

Contact an Engineer about your application

FD Series Sanitary back pressure regulator designed for biopharma and other sanitary processing

Prevent pump push-through