The goal for CIP cleaning in sanitary processes is generally to reach a certain fluid velocity (ft/sec) for a specified time duration. In smaller pipe diameter sizes, this amounts to a small volume of fluid, whereas for large diameter pipes this could reach much larger volumes. Therefore, depending on the design of the process skid, a wide range of flow rates (lpm / scfm) may be required to reach the intended cleaning fluid velocity.

Equilibar FDO fluid control valves are specifically designed for sanitary applications and are particularly helpful in processes such as these where precise control across a wide range of flow rates is required. The FDO can control a range of flow rates at a ratio of 100:1, whereas many traditional flow control valves (FCV) control in a range of 15:1. Additionally, the Equilibar FDO can be set up to control precise pressure or flow depending on how the feedback loop is set up.

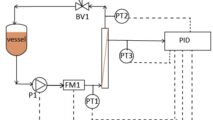

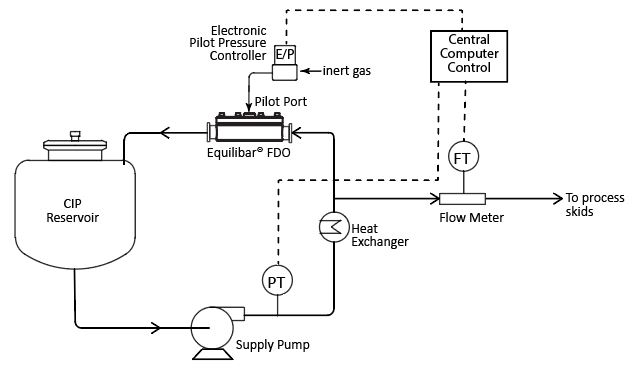

In the schematic above, the CIP system is set up as a recirculation through an Equilibar FDO with feedback from a high resolution flow meter and a pressure transducer. A central computer controls the process for easy automation. During production, the CIP loop recirculates water through the heat exchanger, preparing for the next cleaning cycle. As different skids in the process request CIP cleaning, the fluid flow rate from the CIP system has to ramp up quickly to meet the demand. The Equilibar FDO, with its multiple orifice design and supple diaphragm control, adjusts in milliseconds to the new flow setpoint.

When one skid finishes a cleaning cycle, another cleaning cycle begins potentially with a new flow rate setpoint to reach the proper fluid velocity. Traditional valves may take time to reach the desired setpoint during transitions, but because the Equilibar valve can transition from flow control to pressure control with very simple control logic, it can reduce the period of unstable flow. Shorter transition times between cleaning cycles can save money and reduce cleaning time.

See the video below of an FDO4 in flow control across a wide range of flow rates. The FDO4 is a small 1/2″ port valve, but the same principle works with larger valves needed for CIP loops.

Please contact an Equilibar application engineer to discuss your sanitary process application today.

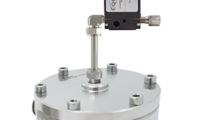

Equilibar FDO16 2″ 316SS control valve