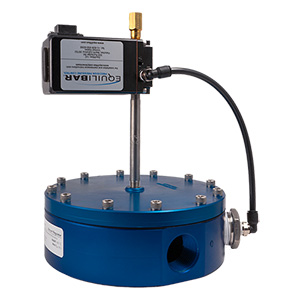

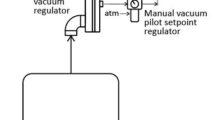

Equilibar® Vacuum Regulators (EVRs) don’t use springs, but instead utilize a 1:1 setpoint pilot pressure on their dome to provide improved precision. This dome-loaded feature also allows for easy computer automation by adding a separate electronic pressure regulator calibrated for the vacuum range (gauge or absolute). (more about how they work)

Automated Vacuum Control using Remote PID Controller in Closed-Loop Mode

In the schematic at right, an electro-pneumatic vacuum regulator (EPR) is connected to the Equilibar Vacuum Regulator to provide the 1:1 setpoint pilot signal. The EPR requires a vacuum supply, which is provided by connecting it to the outlet of the EVR or to a separate vacuum supply. In this example, a remote PID controller monitors the critical process vacuum and sends a signal to the EPR which makes small adjustments to the setpoint of the vacuum regulator as necessary.

Unlike traditional vacuum valves, however, which are difficult to tune and take significant time to adjust to varying flow conditions, the Equilibar vacuum regulator quickly adjusts internally to changing flow rates. The closed-loop adjustments from the PID controller are not required, but increase the precision of the overall system.

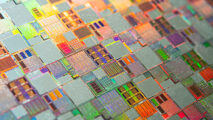

Application Spotlight: Computer Automation of High Vacuum

Some vacuum applications require precise control at very high vacuum in the range of 100 microns Hg (abs) or 0.1 mbar (abs). These conditions can be hard to control, but in a closed-loop setup, Equilibar EVR vacuum regulators can control high vacuum. This may be of particular use in vacuum distillation or other analytical vacuum processes. Below is a video demonstrating high vacuum automation. with an Equilibar EVR.

Automated Vacuum Control using Open-Loop Control

The schematic above shows a simpler system where a Batch Controller adjusts the system vacuum according the process requirements, such as from a Ramp/Soak controller. Because the Equilibar vacuum regulator normally provides good agreement between the pilot setpoint pressure and its inlet pressure, many applications do not require closed-loop control. Discuss your application parameters with our application engineers to determine if open-loop control is viable option for your process.

Closed-Loop Control Without External PID Controller

Electronic pressure regulators are also available with PID controllers capable of monitoring an external pressure sensor. In the schematic above, the pressure sensor is wired directly to the EPR. Note that the EPR still requires a remote analog command signal, such as from an adjustable power supply.

Discuss your vacuum automation application with an Equilibar application engineer to learn the best way to use an Equilibar vacuum regulator for your application