Liquid ring vacuum pumps involve specific challenges. They seem to prefer to be run at a certain vacuum level and if not kept at that vacuum level, they may start spitting oil, water or another fluid. This generally isn’t a problem with the vacuum pump itself, but is an issue resulting from the liquid/gas separators attached to the vacuum pump that are receiving too much mass flow.

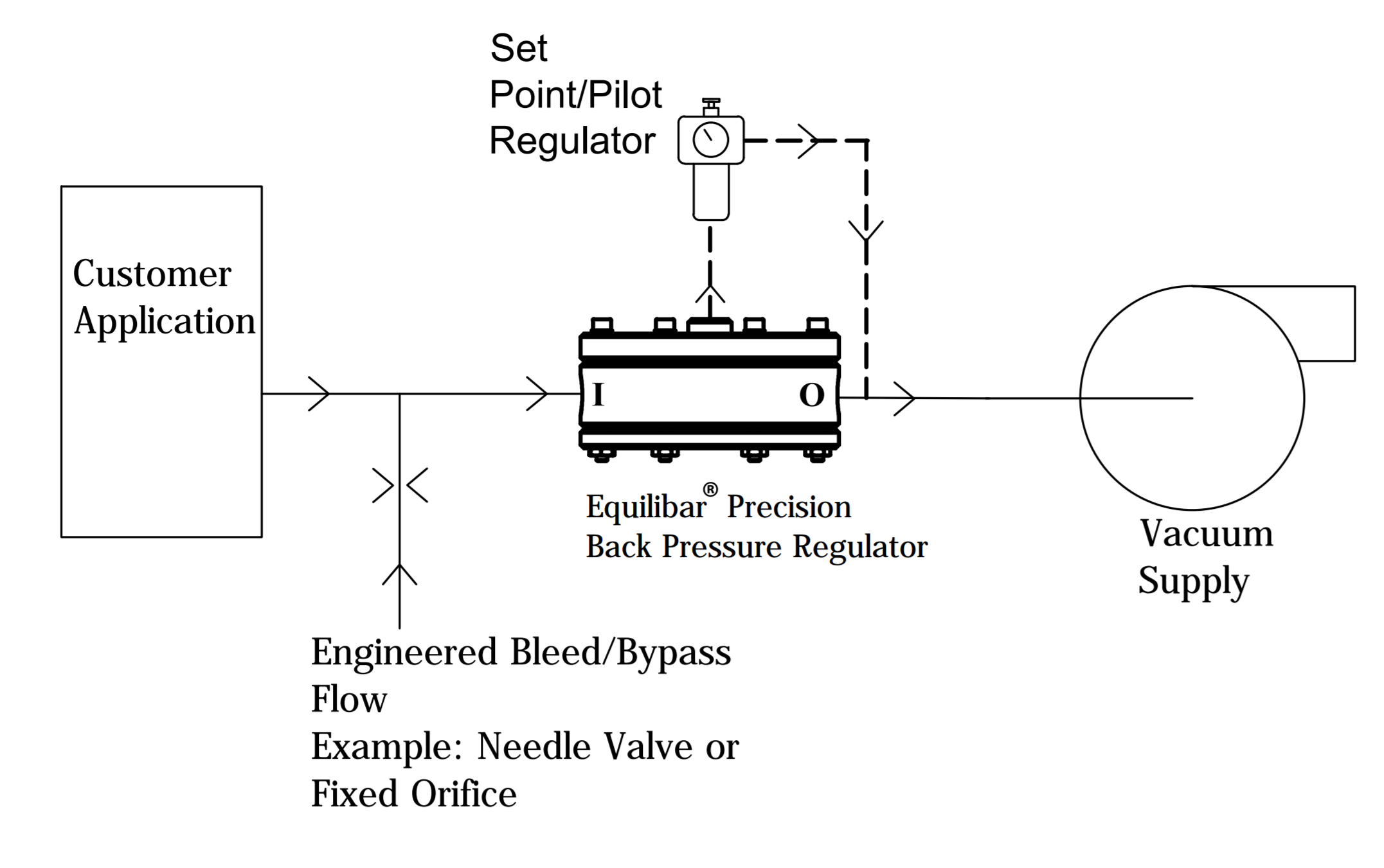

What if a process requires a vacuum level close to atmosphere? Breaking the vacuum by introducing air from a valve or a vacuum breaker can be both messy and put unnecessary wear and tear on the vacuum pump; however, there is a solution. Using a direct acting vacuum regulator, such as Equilibar EVR series vacuum regulators, will control vacuum by limiting the flow instead of ingesting air from the atmosphere. This keeps the liquid ring vacuum pump operating in the optimum range and keeps the surrounding area clean and dry.