The most accurate way to control vacuum in this situation is using a vacuum regulator to throttle vacuum pressure up and down as conditions change in the process or the system. When the container is full and the filling process has a break in vacuum demand, vacuum control still needs to be maintained as not to disrupt the process.

Equilibar® Vacuum Regulators (EVR) are the perfect choice in this application. An EVR will adjust instantaneously to changing process setpoints or changing conditions to maintain accurate setpoint. Some advantages to using an EVR are:

- Extremely fast response to changes in setpoint and upsets in process flow so that when the filling process starts and stops, the vacuum stays in control

- Easily automated by using an electronic pilot setpoint regulator in operations where setpoints need to be changed frequently

- Maintains precise vacuum setpoint to avoid damaging containers or equipment

Applications using a vacuum filling process include beverages, pharmaceuticals, household liquids and dielectric oil.

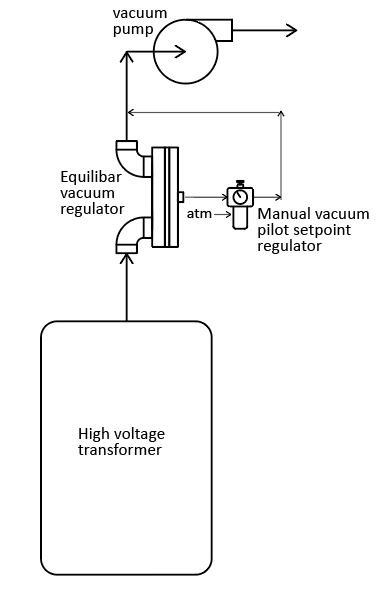

Application Spotlight – High voltage transformer vacuum filling

Level and quality of dielectric oil is important for high voltage transformer equipment to operate properly. The oil dissipates heat and protects the insulation. Dielectric oil is typically vacuum-filled into the transformer tanks when needed at installation or after maintenance.

The filling process is important. Pulling a vacuum on the transformer tank during filling removes bubbles which, if not eliminated, cause the oil to decompose, compromising the life of the transformer. Precise vacuum control allows oil to fill at a desired rate to maintain product integrity and allow for accurate level control. Vacuum flow rate during fill depends on the size of the transformer tank and must be properly set.

An Equilibar vacuum regulator can meet the challenges of vacuum filling for high voltage transformers. With their multi-orifice design, Equilibar EVRs can control vacuum across a wide range of flow rates to a precise setpoint. Whether for integrated vacuum filling on smaller transformers or for contract vacuum filling for large transformers, Equilibar vacuum regulators are a good fit for this application.

Equilibar vacuum regulators are dome-loaded meaning the setpoint of the vacuum is controlled by a standard pressure regulator applying a vacuum to the dome of the EVR. The vacuum setpoint regulator can be manual or electronic. In the example above, the vacuum setpoint regulator is manual, but in cases where automation is preferred, an electronic vacuum regulator can be used. The supply for the vacuum regulator can come from the process vacuum supply pump.

Learn more about how Equilibar vacuum regulators work.

Contact an Equilibar application engineer to discuss your vacuum filling application.

An Equilibar EVR controlling vacuum filling of a high voltage transformer

How the Equilibar High Speed Vacuum Regulator Works

The Equilibar vacuum regulator is pilot operated and has a flexible diaphragm membrane as the only moving part. A pilot vacuum setpoint pressure is applied to the top of the diaphragm. Once the vacuum level in the system is equal to the pilot vacuum setpoint, the diaphragm will move to throttle the flow from the system to the vacuum supply. The flow rate will be automatically limited to exactly the amount that is required to keep the system vacuum pressure equal to the pilot setpoint vacuum level. If the flow rate into or out of the system is suddenly increased or decreased, the diaphragm will instantly adjust to keep the vacuum pressure at the desired setpoint. If the setpoint changes, the diaphragm will adjust to meet the new setpoint.

Learn more about the Equilibar high speed vacuum regulator in this video