Equilibar back pressure valves have a unique design that offers lightning fast response and precision control. By using a frictionless diaphragm, multiple orifices and dome-loaded design, Equilibar high flow valves will maintain a precise pressure across a very wide range of flow rates.

IC Series

High Flow / Medium Pressure Valves

Line size 1½” to 2″ – SS316

Maximum Pressure of 300 psig / 21 bar(g)

Maximum Cv of 60

BD Series

High Flow / Medium Pressure Valves

Line size 1½” to 4″

SS316, PVC or PVDF

Maximum Pressure of 400 psig / 27 bar(g)

Maximum Cv of 160

HV Series

Maximum Flow / Low Pressure Valves

Line size 2″ to 6″

Available in SS304 & SS316

Maximum Pressure of 10 inWC

How it Works

Equilibar back pressure valves function by using a compressible gas setpoint on their dome. They are “ dome-loaded”. For example, if you want to control 100 psig / 69 bar(g) on the inlet port of the valve, simply apply a 100 psig / 6.9 bar(g) set-point of air or other gas to the dome.

The frictionless diaphragm blocks flow in the lower position until the inlet pressure rises to raise the diaphragm.

Unlike traditional back pressure valve designs, the unique Equilibar can respond to severe system fluctuations within milliseconds.

More

- More about backpressure valves – how they work

- Using back-pressure valves to control pump pressure

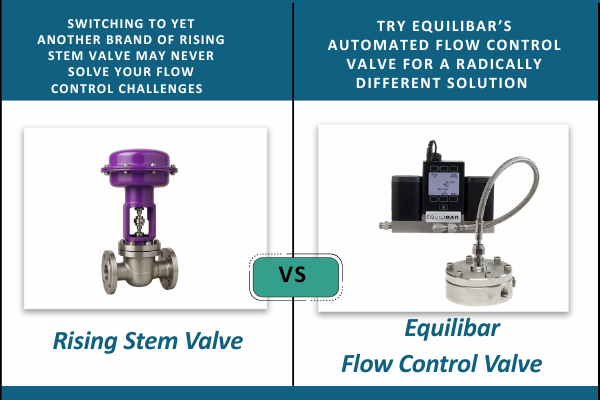

- Compare back pressure valves to traditional control valves.

- Case Study: Using a backpressure valve to control biogas from digestor

- What is a back-pressure valve or back-pressure regulator ?