Equilibar precision vacuum regulators (EVR) are designed specifically to control a highly stable inlet pressure across widely varying input conditions. The EVR maintains tight control despite variation in supply vacuum or changes in flow rate. Equilibar precision vacuum regulators work differently than traditional vacuum control valve designs. They use a flexible diaphragm as the only moving part. This diaphragm is used to directly seal against the internal valve orifices, eliminating the “stiction” commonly found in traditional vacuum control valves that rely on dynamic O-ring or wiper type seals. The Equilibar design is frictionless and can control vacuum with very high resolution. Learn more about how they work.

Equilibar lower flow precision vacuum regulators are available in sizes ranging from 1/4″ to 1″ with material options of stainless steel 316/316L, anodized aluminum or PVC depending on the application requirements for temperature and chemical resistance. Each EVR is delivered with a manual pilot setpoint regulator for convenient knob adjustment.

- For larger vacuum regulator sizes, see our Precision High Flow Vacuum Valves page

- For computer automated vacuum regulators, see our Electronic Vacuum Regulators page

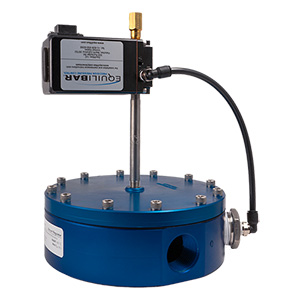

1/2″ EVR-GDS4 with Manual Pilot Setpoint Adjuster

Information about lower flow EVR series options is detailed below. Contact an applications engineer for more assistance.

Metal Vacuum Regulator Details

| Model | Inlet / Outlet Port inch (DN) | Reference Port | Std. Body Materials | Diameter (Dim A) | Height* (Dim B) | Cv Range (Precision) | Available End Fittings | ||

|---|---|---|---|---|---|---|---|---|---|

| inch (mm) | Min | Max | Std | Available | |||||

| EVR-GSD2 | ¼” (8) | 1/8″ | SS316 (SS) Anodized Aluminum (AA) | 3.0 (76) | 1.3 (33) | 1E-3 | 1.2 | NPT | Vacuum Flange BSPP; SAE |

| EVR-GSD3 | 3/8″ (10) | 3.5 (89) | 1.4 (36) | 1E-3 | 1.8 | ||||

| EVR-GSD4 | ½” (15) | 4.5 (114) | 1.6 (41) | 1E-3 | 3.2 | ||||

| EVR-GSD6 | ¾” (20) | 6 (152) | 2.0 (51) | 1E-2 | 5.5 | ||||

| EVR-GSD8 | 1″ (25) | 7 (178) | 2.6 (66) | 1E-2 | 8.5 | ||||

| *Height does not include 3″ manual set point regulator. | |||||||||

PVC Vacuum Regulator Details

| Model | Inlet / Outlet Port inch (DN) | Reference Port | Std. Body Materials | Diameter (Dim A) | Height* (Dim B) | Cv Range (Precision) | Available End Fittings | ||

|---|---|---|---|---|---|---|---|---|---|

| (inch) | Min | Max | Std | Available | |||||

| EVR-GSD2 | ¼” (8) | 1/8″ | PVC | 3.3 (83) | 1.5 (38) | 1E-3 | 1.2 | NPT | Vacuum Flange BSPP; SAE |

| EVR-GSD3 | 3/8″ (10) | 3.8 (95) | 1.6 (41) | 1E-3 | 1.8 | ||||

| EVR-GSD4 | ½” (15) | 4.8 (121) | 1.8 (46) | 1E-3 | 3.2 | ||||

| EVR-GSD6 | ¾” (20) | 6.3 (159) | 2.3 (57) | 1E-2 | 5.5 | ||||

| EVR-GSD8 | 1″ (25) | 7.3 (184) | 2.9 (74) | 1E-2 | 8.5 | ||||

| *Height does not include 3″ manual set point regulator. | |||||||||

Other Equilibar Vacuum Control Products:

High Precision Vacuum Regulators

1/4" to 1"

0 - 30 inHg / 762 mm Hg

High Precision Vacuum Regulators

1/4" to 1"

0 - 30 inHg / 762 mm Hg

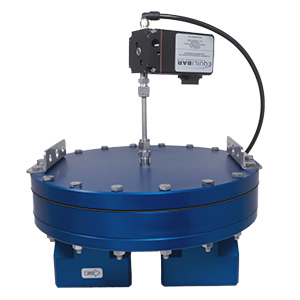

High Flow Vacuum Valves

1.5" to 4"

0 - 30 inHg / 762 mm Hg

High Flow Vacuum Valves

1.5" to 4"

0 - 30 inHg / 762 mm Hg

Electronic

Vacuum Regulators

1/4" to 1"

0 - 30 in Hg / 762 mm Hg

Electronic

Vacuum Regulators

1/4" to 1"

0 - 30 in Hg / 762 mm Hg

Larger Electronic

Vacuum Valves

1.5" to 4"

0 - 30 in Hg / 762 mm Hg

Larger Electronic

Vacuum Valves

1.5" to 4"

0 - 30 in Hg / 762 mm Hg

Vacuum

Pilot Regulators

mechanical, electronic

and remote sensing

Vacuum

Pilot Regulators

mechanical, electronic

and remote sensing

Videos about Precision Vacuum Regulators

This video discusses the difference between a vacuum breaker and a direct vacuum regulator, like the Equilibar. It shows how the Equilibar direct vacuum regulator maintains high accuracy even as the system flow rate varies.

Follow this link to watch a video about vacuum control for high flow rates.