Stainless Steel 316 Construction for Corrosion Resistance

Stainless steel Type 316L is a popular material for Equilibar BPRs for its excellent corrosion resistance to most chemicals. Learn more about our stainless steel regulators.

Hastelloy and Custom Metal Alloys

Hastelloy or other metal alloys are preferred for specific fluids where 316L stainless steel is not the best choice for compatibility. For these situations, Equilibar offers:

- Hastelloy C276 / Hastelloy C2000 / Hastelloy C4

- Monel

- Titanium

- Zirconium

- AL-6XN

100% PTFE (Teflon®) Construction

Many PTFE fluid control devices sacrifice precision in order to meet high purity or chemical compatibility. However, the elegance of Equilibar diaphragm technology allows for incredible precision even with 100% PTFE construction.

- Our 100% PTFE Teflon regulators are sensitive to 0.001 psig / 0.069 millibar(g) and can control down to 0.02 psig / 1.38 millibar(g).

- PTFE bodies with pipe threads can be used for vacuum, ultra low pressure, or back pressure applications up to about 50 psig / 3.4 bar(g).

- Equilibar offers higher pressure ports for 1/8″ and 1/16″ tubing that allows PTFE Teflon regulators to reach 500 psig / 34 bar(g).

- Metal alloy bodies are available with PTFE diaphragms for applications up to about 2500 psig / 172 bar(g) (depending on the details of the application).

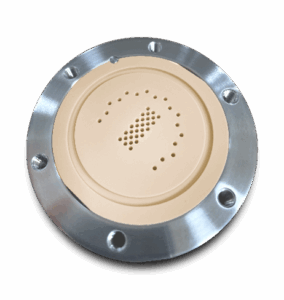

PVDF and PEEK for Strength and Chemical Resistance

Polymers such as PEEK and PVDF offer chemical resistance to a wide variety of aggressive chemicals and are significantly stronger than PTFE. These materials make a good alternative where pressures are too high for the softer PTFE. As shown at right, pipe flanges can be welded to the bodies of PVDF regulators.

Equilibar Regulators for Chemical Resistance at High Pressure

Equilibar regulators designed with a metal cradle supporting a polymer body provide chemically compatible options for even more severe chemical applications, including high pressure gas. Polymer inserts and other wetted components can be customized to fit your specific process needs. These valves are suitable for microreactors, pilot-scale systems, or full-scale productions systems.

- Stainless Steel cradle design allows for pressures up to 1500 psig / 103 bar(g)

- Regulator body available in PEEK, PTFE, PVDF and CPVC

A common application that requires a full-polymer flow path is Continuous Flow Chemistry. These processes commonly utilize corrosive chemicals and high pressures which other traditional pressure regulators may fail to accommodate

Contact an EngineerSilcoNert Coating Provides Protective Barrier

SilcoNert® is a chemically protective barrier of amorphous silicon, applied by chemical vapor deposition, that provides an inert surface especially for sulfurs, mercury and ammonia. Equilibar offers back pressure regulators with SilcoNert coatings.

Diaphragm Materials and Sealing materials

Equilibar diaphragms are available in a wide variety of materials, including PTFE, PEEK, Polyimide, Viton, Stainless Steel 316, and Hastelloy. Each customer inquiry is reviewed by our application engineers who provide input for the best diaphragm material to use based on the specific conditions.

Although most Equilibar valves are available without any wetted seals or O-rings, those models incorporating O-rings are typically supplied with Viton, with available upgrade to Kalrez. Speak to an engineer about your particular situation.

Contact an EngineerNACE MR0175/ISO 15156

The National Association of Corrosion Engineers and ISO publish the NACE MR0175/ISO 15156 Standard, providing requirements and recommendations for selecting alloys for service in equipment that will be used in oil and gas production in H2S-containing environments. The standards are written to avoid sulfide stress cracking of equipment used in sour service applications. Equilibar engineers are available to speak to you about your application to find a regulator that meets these NACE standards.

Learn more about our chemical resistant options:

316L Stainless is the most common material for Equilibar BPRs

Equilibar BPRs are available in Hastelloy and other alloys.

PTFE body and diaphragm for aggressive chemicals at lower pressures

Flanged Equilibar GSD8 made from PVDF for harsh chemistry applications

PEEK Equilibar CHF – PEEK HF with a 316L SS cradle for high pressure processes needing specific chemical compatibility