Multi Use and Single Use Valves for Biopharma Processing

Equilibar valves for the biopharmaceutical industry improve process control to deliver better outcomes. The Equilibar dome-loaded multiple orifice design with supple diaphragm results in extreme precision and rapid response for critical biopharma applications.

Industry Insights

Biopharmaceutical processing demands high performance equipment designed for sterility, flexibility, compliance and control. Key features for bioprocessing components include compliance with ASME BPE, hygienic designs, high precision automation, scalability, ease of maintenance and compact footprint. The equipment must not only work well but also consistently produce safe, high-quality biologics under GMP conditions.

Biopharmaceutical manufacturers face constant pressure to improve efficiency while ensuring compliance, sterility, and precise process control. Equilibar’s dome-loaded diaphragm technology delivers exceptionally stable performance across a wide flow range, reducing buffer waste, improving automation, and streamlining facility layouts. Fully supported by regulatory documentation and certifications, our biopharma valves scale seamlessly from single-use development to full-scale stainless production. In conjunction with Steriflow Valve and Jordan Valve products, Equilibar is more than a component supplier — we’re your partner for solutions to the evolving challenges of modern bioprocessing

Contact Us

Equilibar FD Sanitary Series

- Simple compact design makes them easy to maintain and streamlines facility layout

- Stability across a wide flow range – wider than other valves on the market.

- Smooth computer automation. Because they respond instantaneously to flow or setpoint changes, they are perfect for automation. Just pair with an electronic pilot regulator.

- Versatility – designed to regulator pressure but can be set up in a control loop to control flow as well

- Perfect for multi-use and hybrid systems

Equilibar SD Single-Use Valves

- Industry’s first single-use back pressure regulator

- Precise control over a wide range of flow rates

- versatile – use for back pressure regulation or flow control

- Stainless steel cradle mounts in place while polymer valve is changed out when needed.

- Injection molded valve body and thermally welded diaphragms

- ISO Class 7 clean room assembled, double-bagged and ready for sterilization up to 50 kGy

- Keyway system to ensure proper installation

- Documentation & traceability with every order

Biopharma Applications

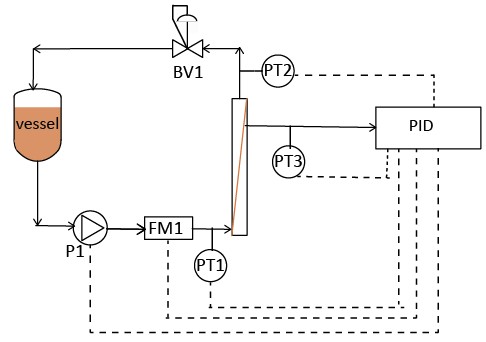

Optimizing TMP Control to Improve Bioprocess Filtration

Understanding TMP control for TFF from a fluid mechanics standpoint can help in designing an efficient process. In bioprocessing operations...

Learn More

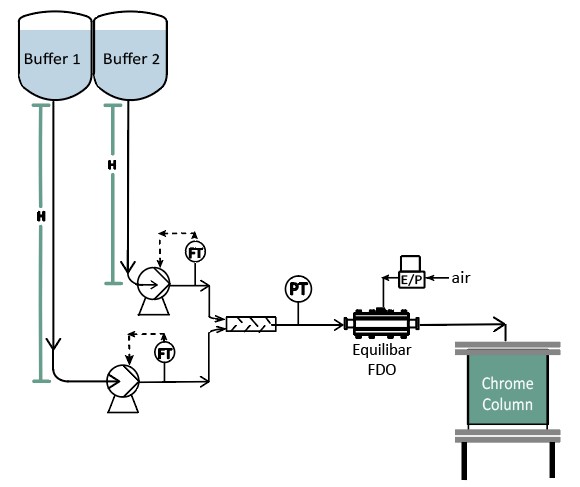

Preventing pump push-through flow in sanitary processes

In the intricate landscape of bioprocessing, maintaining the purity and integrity of biological substances is essential. Sanitary pumps are integral...

Learn More

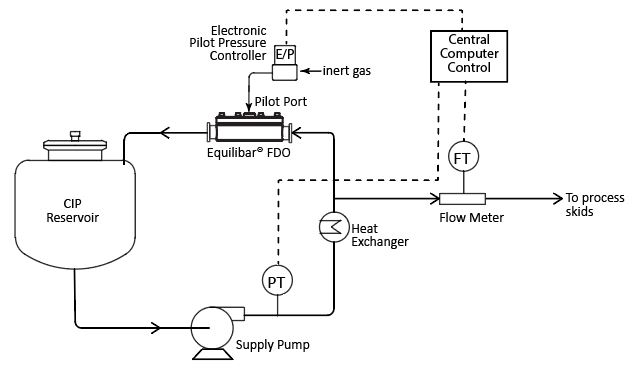

Precision flow control in CIP cleaning cycles

In many large biopharmaceutical plants, there are central clean in place (CIP) systems that provide cleaning processes to all the...

Learn More