Equilibar is proud to announce that it has been awarded ISO 9001:2015 certification. This milestone continues the company’s commitment to providing pressure regulators of the highest quality to clients in research and industry around the world.

The ISO standard, which was developed by the International Organization for Standardization, establishes a uniform set of measurements for international manufacturers to gauge quality management systems.

“Equilibar selected Hartford Steam Boiler (HSB) as their ISO Registrar,” said Operations Manager David Reed. “HSB was selected specifically because their long history of working with pressurized boilers allowed them to be familiar with the very same pressure codes that govern the design and manufacture of Equilibar’s pressure regulators.”

In order to earn certification, Equilibar had to demonstrate excellence in the way the company achieves customer satisfaction, continuous improvement and other key goals.

“We are especially happy to have achieved this goal during the year we are celebrating our tenth anniversary,” David said. “This achievement was something we wanted to pursue for our own objectives and is a crucial step in assuring that our clients always receive the best in quality and service. Assessment by a respected independent organization assures that we are following world-class practices.”

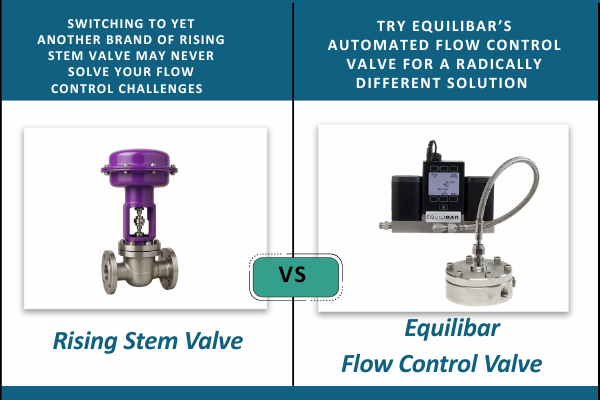

Equilibar offers novel pressure control technology for research and industry, including catalysis, core analysis, and membrane separation. Equilibar’s signature back pressure regulator features a dome-loaded, multiple orifice design that provides instantaneous control for even the most challenging applications. The design uses a supple diaphragm as the only moving part, delivering frictionless operation and a level of precision that is not possible with traditional spring-loaded valves and regulators. Equilibar also offers electronic regulators, pressure reducing valves, blockage resistant regulators for supercritical extraction, and mity mite replacement valves. Equilibar’s engineering team is experienced in pressure control and works collaboratively with customers. For more information, visit https://www.equilibar.com/ or contact an application engineer at inquiry@equilibar.com.