A new white paper explains how an Equilibar® can be used in combination with a mass flow sensor to provide reliable flow control for particularly difficult research applications. While Equilibar’s ability to provide excellent pressure control is well known, fewer scientists and engineers are familiar with using it for flow control, making the paper especially useful.

The paper focuses on a parallel test reactor system designed by ILS-Integrated Lab Solutions, a Berlin-based fabricator of high-throughput to pilot scale catalyst testing workflows. ILS researchers constructed the system for a supplier of Vinyl Acetate Monomer (VAM) catalysts. VAM is an industrial chemical used in the production of various polymers. Its synthesis is challenging for several reasons, including the fact that feed vapors must be maintained in the vapor phase, which requires a temperature of 200°C.

Unfortunately, most commercial thermal or Coriolis mass flow controllers suitable for operation at the low flow rates used in laboratories are not able to work at temperatures above about 70°C.

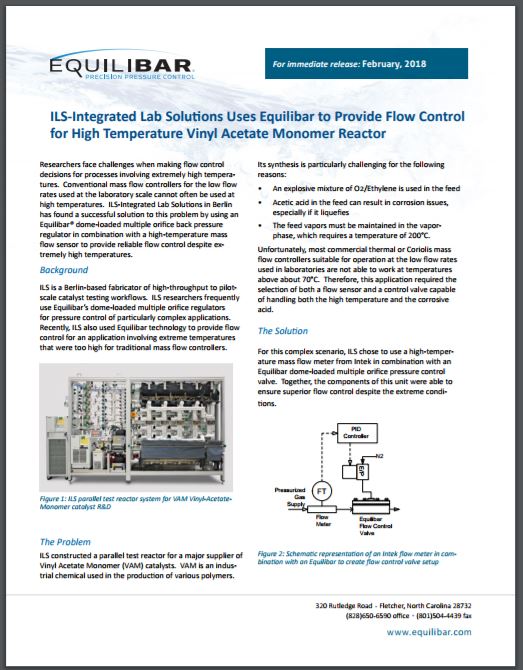

To get around this problem, ILS chose to use a high-temperature mass flow meter from Intek in combination with an Equilibar Research Series dome-loaded multiple orifice pressure control valve. Together, the components of this unit were able to ensure superior flow control despite the extreme conditions. Specifically, ILS used a Siemens process-control system to control the nitrogen dome pressure head on the Equilibar via an electronic pressure controller. With this setup, it was possible to control flow via the dome pressure of the Equilibar, which was operating in a feedback control loop between the electronic controller and the Intek flow meter.

The paper also explains what happened when an unexpected event occurred and showed that the flow control setup was even more adaptive and capable of handling challenges than anticipated. For more details, read the complete white paper here.