Precision Pressure and Flow Control for Hydrogen Systems

Equilibar® valves deliver precise, reliable control for a variety of hydrogen applications including fuel cell and electrolyzer test systems, and electrolysis emergency shut-down. Built to perform under a range pressures and temperatures while responding to dynamic conditions, they help engineers push hydrogen technology forward with confidence.

Industry Insights

Reliable pressure and flow control are critical for advancing hydrogen technologies, where safety, efficiency, and precision are top priorities. From hydrogen production to component testing to filling stations, hydrogen processes demand valves that perform consistently under challenging conditions such as high pressures, high temperatures, wide flow ranges, and rapid system dynamics.

Equilibar® valves are engineered to deliver unmatched stability and responsiveness, giving engineers the confidence to optimize performance while meeting rigorous industry standards. With innovative dome-loaded designs and robust materials, Equilibar solutions help drive the future of hydrogen energy.

Contact Us

Equilibar IC Series Back Pressure Regulators

- Robust design for industrial applications needing higher flow and larger line sizes (1.5″ – 4″)

- Fast response times

- Precision across a wide range of flow rates

- High pressure options – Class 150 and 300, designed to ASME B16.34 standards

- Premium materials – Standard dual-certified CF3M/1.4409 stainless steel body material with Hastelloy and most nickel-based alloy options available upon request.

- Flexible process connection options – NPT, ANSI RF flange, and tri-clamp fittings stocked standard. DIN flanges, BSPP threaded ports, and other connections available upon request

Equilibar GS Series

- Sized for pilot plants and industrial applications with line sizes (1/2″ to 1″)

- Stability across a wide flow ranges, with unmatched 1000:1 flow turn-down ratio.

- Precision control for gas, liquids, and multiphase fluids

- High sensitivity in the low to mid pressure ranges that is lacking in many competitive products.

- Capacity to control multiphase fluids with extreme precision due to its unique multi orifice design.

- The dome-loaded control allows it to easily pair with an electronic controller for superior automation.

Hydrogen Applications

Electrolysis emergency shutdown valves

Electrolysis systems for hydrogen generation use an electric current to dissociate water into hydrogen (H2) and oxygen (O2) molecules. Popular...

Learn More

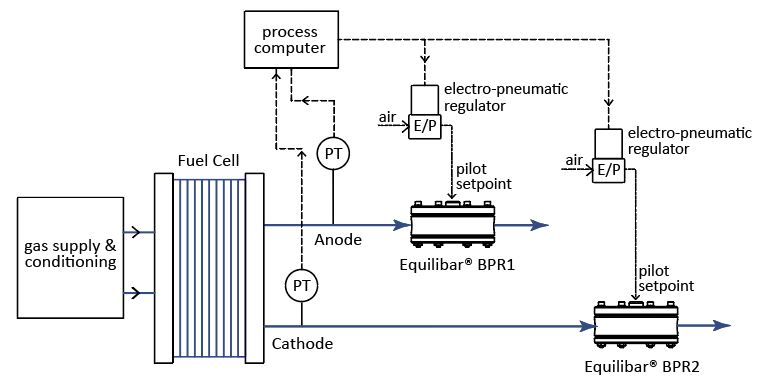

Fuel Cell Pressure Regulator

Key performance characteristics for fuel cell pressure control The Equilibar® precision back pressure regulator (BPR) is the perfect fit for...

Learn More

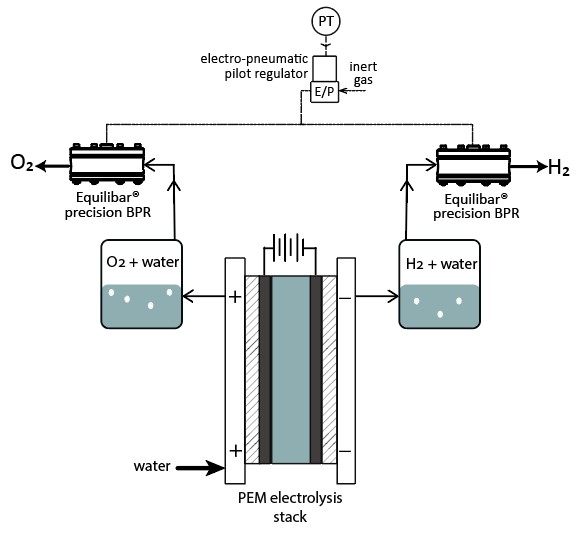

Electrolysis and Electrolyzer Pressure Control

Electrolysis uses an electric current to energize a chemical reaction that will not occur naturally. Water electrolysis is an electrochemical...

Learn More