A recently published case study highlights Equilibar’s role in clean energy research, a field gaining urgency as countries around the world work to reduce the environmental impact of carbon fuels, with some new regulations going into effect this month.

In the oil and gas industry, removing impurities from petroleum fuels is an important way to make emissions cleaner. Hydrodesulfurization (HDS) and hydrodenitrogenation (HDN) are chemical processes that use catalysts to remove sulfur and nitrogen impurities. New legislation such as IMO 2020 for marine fuels and Tier 3 for automotive fuels requires substantial reductions of sulfur and nitrogen to reduce their environmental impact.

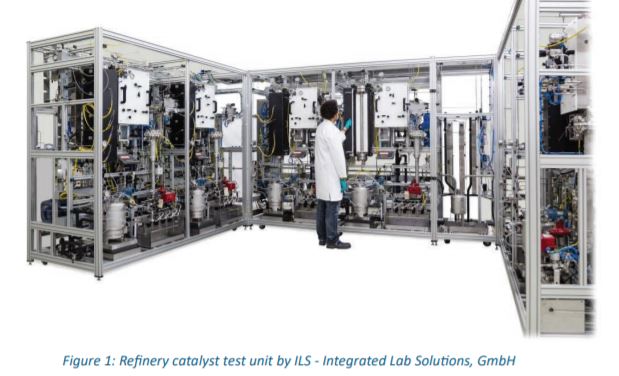

Berlin-based ILS-Integrated Lab Solutions, GmbH has extensive experience with deep HDS and HDN research applications in which exceptionally low flow rates and high pressures are needed. ILS researchers have had repeated success using Equilibar fluid controllers for these complex scenarios. The new case study demonstrates how this is done.

Equilibar’s technology is uniquely well suited for two-phase flow because it uses a direct sealing diaphragm over multiple orifices to control the pressure drop (see how it works). The valve action is not provided by the movement of a tapered stem, but by the close proximity of the diaphragm and the orifice plate. The supple diaphragm can vary its proximity to the orifice nearly instantaneously to adjust to the varying valve coefficient requirements of the various phases. A further benefit is provided by the unique multiple orifice design. Even if one orifice is totally flooded by the denser liquid, volumetric flow control can still be maintained so long as some of the orifices are still predominantly in the gas phase.

“The design of Equilibar controllers is unique,” said Dr. Anton Nagy, founder of ILS. “They have a definite advantage for two-phase flow and catalysis.”

We invite you to read the case study in its entirety for more details on this exciting research. As always, feel free to contact one of our engineers with questions and ideas about using Equilibar for challenging flow, pressure or level control applications.