As more and more hazardous materials are being produced around the globe, the need to find better ways to eliminate toxic waste has gained urgency. Stuart Moore, a researcher in the Mechanical Engineering Department at the University of Washington-Seattle, is exploring a promising new method that uses a supercritical water oxidation (SCWO) reactor to destroy dangerous chemical wastes, including chemical warfare agents and the forever chemical perfluoro-octane sulfonate.

Because SCWO is an emerging and complex technology, it presents multiple challenges, including maintaining reliable pressure control of the reactor. Stuart and his colleagues have found that the direct-sealing diaphragm valve technology of Equilibar® back pressure regulators (BPRs) offers several advantages for the extreme service conditions encountered when working with supercritical fluids.

Problems with existing methods of destroying toxic waste

Common methods of destroying dangerous chemical waste include incineration and/ or disposal in a landfill. Both methods can be problematic. Incineration, for example, reduces the volume and toxicity of waste but still emits flue gas to the atmosphere, which can contain heavy particulates, and produces contaminated ash that must then go into a landfill.

Aqueous wastes are particularly difficult to destroy because most of the waste is water, which the incinerator must heat to destruction temperatures, thereby wasting energy.

Advantages of SCWO

In contrast, the SCWO reactor uses the water within the solution to destroy itself, without producing harmful emissions or ash, making the method safer, less polluting and more energy efficient.

Stuart is a Ph.D. graduate student and research assistant in the Novosselov Research Group of the University of Washington—Seattle. In conducting SCWO research, he initially used a traditional style BPR for the reactor. “The device was too sensitive to particulates, however, and would fail regularly,” he said. “We needed a more robust, high-pressure BPR to handle some particulate flow.”

Moore worked with engineers from Equilibar to select a research series H6P BPR, which is designed for high pressure applications. They chose a body made of stainless steel with Viton O-rings and PEEK diaphragm. Configured this way, the device is rated for 4500 psi and up to 100° C. The H6P proved capable of competently handling the small-particulate flow of a mixture of gases and liquid. Moore reports that he has had zero problems and no downtime since switching. By contrast, the previous traditional BPR required periodic maintenance to replace gaskets and clean the orifice and needle.

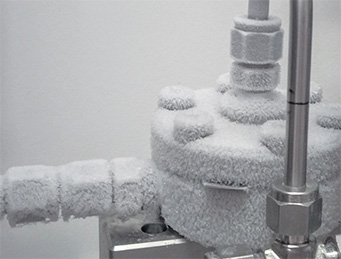

Below is a schematic of the complex reactor setup.

How It Works

Equilibar BPRs use a direct-sealing diaphragm technology in which a thin diaphragm covers a field of parallel orifices. Inside the BPR, the diaphragm is positioned between the main body and the reference cap. The main body contains orifices that are covered and sealed by the diaphragm when they are not engaged. The device is controlled with pneumatic pilot operation at a 1:1 ratio, which means that gas or air is fed into the top (dome) area of the BPR to provide the pressure setpoint for the process. The pressure of the gas in the dome is set by a secondary standard regulator called a pilot regulator. As fluids flow through the BPR, the thin and supple diaphragm lifts off the orifices to release pressure once the setpoint is reached. When flow is minimal, only a portion of one orifice will open. When flow is high, the diaphragm is pushed up to engage more orifices.

The responsiveness and flexibility of the diaphragm engaging with the multiple orifices result in an extremely versatile flow rate range. For fluids with particulates, the H6P’s multiple orifices are especially helpful as they allow multiple flow paths. If one orifice begins to restrict, the remaining orifices compensate for the change in flow to allow for continuously smooth and accurate pressure control.

For more information on this application, please read the case study in full: Equilibar valve controls supercritical water oxidation system to destroy toxic waste (equilibar.com) You may also be interested in an interview with Dr. Igor Novosselov, who heads up the research group exploring SCWO and other cutting edge studies at the University of Washington-Seattle. Q&A: UW researchers develop a reactor that can destroy ‘forever chemicals’ | UW News (washington.edu) as well as an earlier Equilibar case study regarding pressure control for supercritical water reactors: Case Study:Equilibar Technology used in Supercritical Water Reactor

And, as always, please contact one of our experienced application engineers with your fluid control challenge.