Over the summer, I began hearing more and more about NASA’s Artemis program, the successor to the Apollo missions of the 1960s. The goal of Artemis is to land “the first woman and the next man” on the moon by 2024 as well as establish a sustainable lunar presence and travel to Mars.

A few weeks ago, Equilibar received an email from a reporter with our local newspaper who wanted to do a story about our role as a supplier for Artemis. This was pretty exciting for us, especially since we didn’t know our devices were being used in the Artemis program!

How is this possible? Since the beginning of our company in 2007, we’ve been lucky to provide valves for a variety of NASA projects, including acoustic stress testing for launches and thermal testing for telescopes. We’ve had 29 orders from NASA involving 12 of their locations. The original order for NASA’s Artemis project was made several years ago, before many people had heard of the mission. It was a relatively straightforward request for a regulator that would be used to vacuum bond a large surface. Since it didn’t require a lot of custom engineering, we didn’t get overly involved.

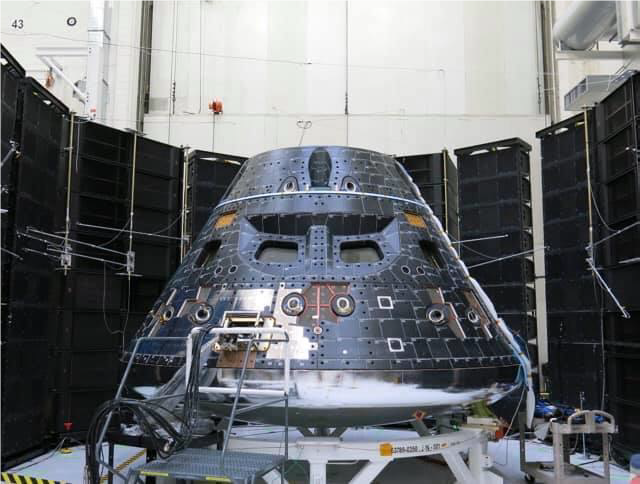

After the reporter made us aware of our connection to Artemis, application engineer Alan Black and Diane Jacober, mechanical engineer and technical content creator, tracked down the details of the order. Diane learned that our valves are at Kennedy Space Center’s Neil Armstrong Operations & Checkout Facility. The valves regulate pressure on vacuum bonding carts, which are used to bond tiles to build up the Thermal Protection System on the aeroshell for each Orion spacecraft. The aeroshell protects the vehicle and crew from thermal loads during re-entry.

The carts have been used to bond every tile on the spacecraft for Artemis 1 and are now being used on Artemis 2. The largest surface to bond is the heatshield, which is just over 16 feet in diameter. This is a quite challenging scenario and I’m happy to say that our valves are performing well.

The carts have been used to bond every tile on the spacecraft for Artemis 1 and are now being used on Artemis 2. The largest surface to bond is the heatshield, which is just over 16 feet in diameter. This is a quite challenging scenario and I’m happy to say that our valves are performing well.

Diane has created an application page to illustrate how our valves can be used for vacuum bonding projects such as this one, and I hope you will take a few minutes to look at it, especially if you have a similar situation.

Learning that our vacuum regulators are playing a key role in such a momentous project is highly gratifying. I’m looking forward to watching the launch in 2024. But in many ways, it’s even more gratifying to realize that this is one of many, many amazing projects we’re involved in. Even better, each day brings us something new. I believe we’ve only begun discovering the potential uses for our products.

Photo courtesy of NASA.