Customer service and product quality are a top priority at Equilibar. We know our customers are choosing Equilibar products to meet demanding process conditions, so we purchase premium machinery to manufacture and test our products. Sometimes our customers require replacement diaphragms to be expedited, in which case we do our best to meet those demands.

We have a variety of popular diaphragms in stock which can be shipped within 24 hours. Please email us at inquiry@equilibar.com to find out if yours is available. Additionally, our partners at Pressure Control Solutions in The Netherlands have a wide variety of Equilibar diaphragms in stock for our European customers. Please contact them at info@pressurecontrolsolutions.nl for more details.

Other diaphragm types may not be in stock, so we work with our customer to meet their time and quality demands. In some cases, we can supply exotic alloys with a shorter delivery time when the customer can accept water jet, laser cut or hand cut finish. These diaphragms will not have the same appearance as standard diaphragms, but the quality of the performance of the unit is never compromised. Below are descriptions and images of the various diaphragm production options. Contact us with any questions regarding diaphragm selection.

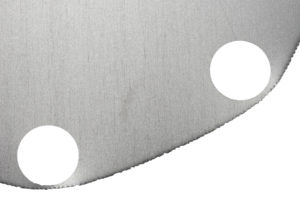

Standard Production Quality

This diaphragm represents the quality found in any standard production shipment. The diaphragm was carefully produced using specialized machinery which results in a blemish free product. Unless you have approved an alternate quality diaphragm after working with an Equilibar engineer, this is the quality of diaphragm you should expect to receive. Some of these are in stock and available to ship within 24 hours. Others will need to be ordered and will have a bit of a lead time. Please email us to find out.

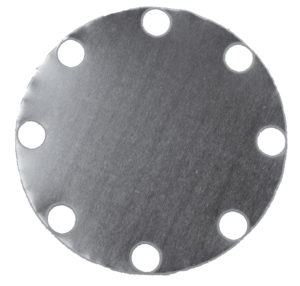

Water Jet Cut

This diaphragm represents the quality that may be found when a new diaphragm shape, thickness, or material is required, but the end user has informed Equilibar that there is not adequate budget or time to produce an out of stock standard production quality part. The water jet cutting process leaves a scalloped appearance around the outer perimeter and the bolt clearance holes. Minor scuffing may be found across the entire surface as a result of the forces required to hold the diaphragm in place while it is cut. These diaphragms tend to be as serviceable as standard production quality but without the nice appearance.

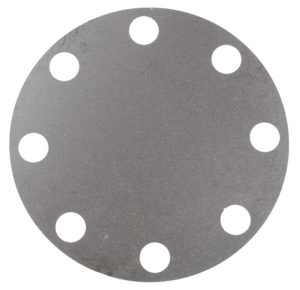

Laser Cut

Laser cutting is rarely used any longer for Equilibar diaphragms. However, many legacy designs utilized the laser cutting method. Older Equilibar regulators that require servicing with a replacement diaphragm may have a laser cut diaphragm pulled from remaining inventory if the end user’s budget or timing does not allow for a standard production quality diaphragm to be produced. Laser cut diaphragms may have varied amounts of slag and flash fused around the perimeter and the bolt clearance holes as well as more prominent scuffing from the fixture holding the diaphragm during the cutting process. Laser cut diaphragms are nearly as serviceable as standard production quality, but have the least desirable appearance.

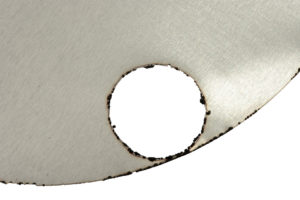

Hand Cut

In certain sizes and thicknesses a hand cut diaphragm may be produced rather than a water jet cut or laser cut. In these instances hand cutting will allow faster shipment. An irregular shaped perimeter and dimpling around the bolt clearance holes will be evident. The surface may have very minor scratches. Performance and service life will generally be identical to standard production quality but appearance will certainly differ from standard.