Equilibar valves for semiconductor applications

Equilibar® back pressure regulators (BPRs) and vacuum regulators (EVRs) provide ultra-stable pressure and vacuum control in critical semiconductor processes, from wafer handling to high purity, specialty gas delivery. With their dome-loaded design and exceptional precision, they ensure fast response and consistent performance in the most demanding cleanroom environments.

Semiconductor Industry Insights

Semiconductor manufacturing, particularly the fabrication of integrated circuits (ICs) or “chips”, is one of the most complex industrial processes ever developed. The processors used in our computers, phones, cars, and appliances are produced via a long sequence of manufacturing steps, each requiring ultra-precise engineering, cutting-edge materials science, and nanoscale fabrication techniques.

Given the challenging nature of the chips manufacturing process, it’s no surprise that Equilibar has helped solve a variety of difficult fluid control problems for our clients. Within these systems, Equilibar has worked on applications needing extremely precise control, compatibility with incredibly aggressive fluids, and exceedingly fast response times. Equilibar back pressure regulators (BPRs) and vacuum regulators (EVRs)

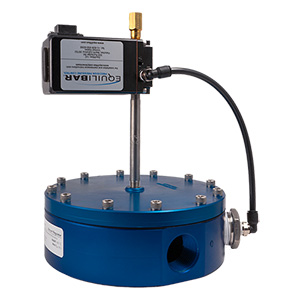

Equilibar Industrial Vacuum Regulators

- Easy to use

- Excellent stability

- Smooth computer operation

- Lightning fast control

Equilibar Industrial Back Pressure Regulators

- Robust design for industrial applications needing higher flow and larger line sizes (1.5″ – 4″)

- Fast response times

- Precision across a wide range of flow rates

- High pressure options – Class 150 and 300, designed to ASME B16.34 standards

- Premium materials – Dual-certified CF3M/1.4409 stainless steel body material with Hastelloy and most nickel-based alloy options available upon request.

- Flexible process connection options – NPT, ANSI RF flange, tri-clamp flanges, DIN flanges, BSPP threaded ports

Equilibar Vacuum Regulator (EVR)

- Direct vacuum regulation (not a vacuum breaker)

- Fast response times to varying vacuum output or process conditions

- Precision down to very small vacuum

- Precision across a wide range of flow rates

- Dome-loaded and easily automated with electronic pilot regulator

Semiconductor Applications

Fluid Control for Semiconductor Fabrication

How do pressure and vacuum play a role in semiconductor manufacturing? Pressure and vacuum regulation play a key role in...

Learn More

Liquid Cooling Loop Control

What is a liquid cooling loop? Liquid cooling loops or chiller loops circulate cooling fluids to a process to keep...

Learn More