For space exploration, the ability to generate enough oxygen for crew members is of primary importance.

On board the International Space Station, an Oxygen Generator Assembly uses flow cell electrolysis to make oxygen from water using a flowing water electrolyzer. Flow cell electrolysis is a common way to facilitate a continuous electrochemical reaction while separating products and providing adequate fluid mixing and reactant distribution.

Many existing electrolyzer designs require a downstream gas-liquid separation process, which presents multiple challenges in a microgravity environment. One complication is two-phase flow caused by bubble generation in the electrolyzer: bubbles can cavitate pumps and reduce efficiency of the electrolyzer.

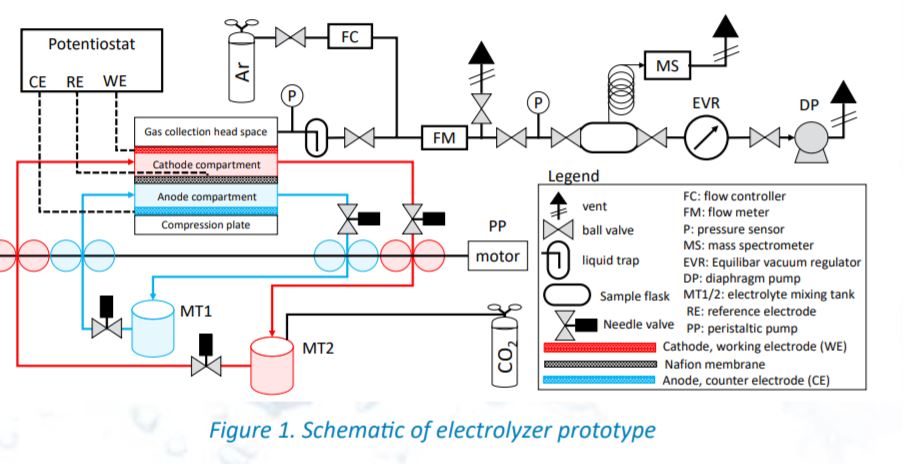

Jordan Holquist, a recent PhD graduate from the University of Colorado at Boulder, proposed an alternative electrolyzer configuration with the objective of high per-pass CO2 utilization efficiency, high-purity gaseous product output and little to no need for downstream gas-liquid separation of products. Holquist’s design is similar to a fuel cell configuration in that a catalyst-coated gas diffusion electrode is used for the cathode, but instead of introducing gas on the backside of the cathode, a coarse vacuum is pulled through an outlet of the gas headspace. The purpose of this vacuum is to separate gaseous products through the electrode as they are generated in a process Holquist calls vacuum-assisted product removal (VAPR). VAPR is similar to what is done in differential mass spectrometry, but on a larger scale.

Since pressure was one of the two main parameters tested in the evaluation of Holquist’s VAPR prototype system, the ability to accurately and reliably control the pressure at the backside of the gas diffusion electrode was critical.

To address this need, Holquist contacted Equilibar engineers to discuss his application. With their input, he was able to use an Equilibar regulator to provide uncomplicated and instantaneous control of the vacuum pressure, making the parametric testing simple and reliable even when dialing in to pressure resolutions down to 0.01 psia. This was possible in part because Equilibar’s novel technology offers superior precision as well as frictionless control.

For more application details, please read the case study here. And as always, feel free to contact an Equilibar engineer to discuss your challenging pressure or flow control situation.