A video recently filmed in the Equilibar laboratory demonstrates a new method of maintaining consistent flow control over a wide range of flow rates–typically 100:1. This is accomplished by using an Equilibar® back pressure regulator with a pilot pressure controller and a flow meter in a PID (proportional-integral-derivative) control loop.

This approach is especially useful when an application has a wide range of flow or when sanitary restrictions or extreme environments are involved. It is also a good alternative for flow chemistry applications.

Traditional flow control valves typically have a ratio of maximum flow rate to minimum flow rate of 10:1. With Equilibar flow control valves, that ratio increases to 100:1. In the video, the Equilibar BPR controls flow from 50 ml/min to 5000 ml/min.

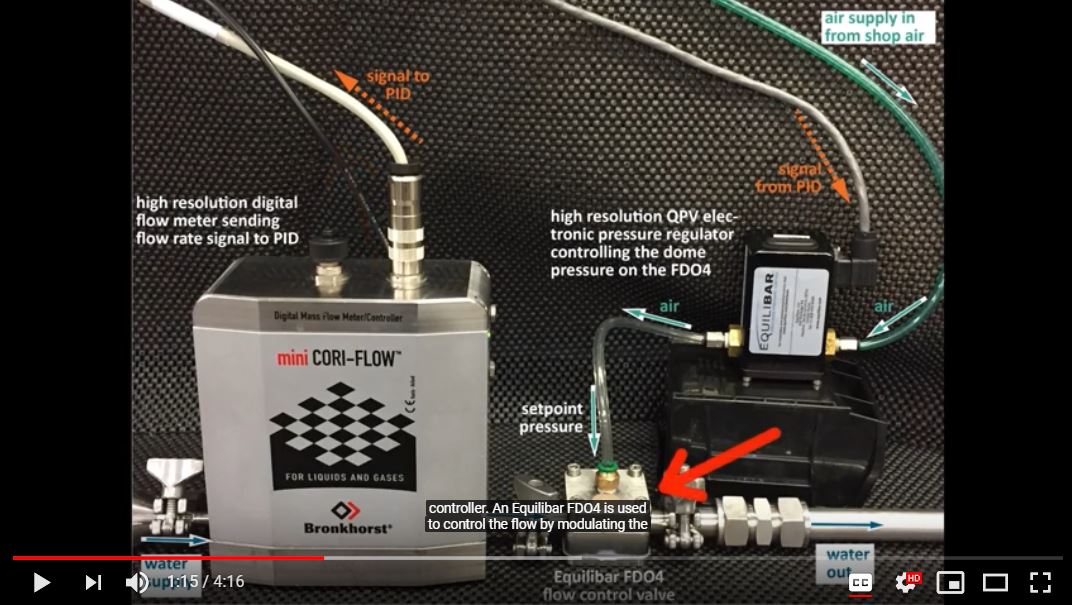

In this flow control configuration, a Bronkhorst® high resolution flow meter is used to send a flow rate signal to the PID controller. An Equilibar QPV electronic pilot regulator translates the electronic signal from the PID to adjust the pilot pressure on the dome of the Equilibar BPR, which controls flow by modulating the pressure at its inlet. Flow is decreased by raising the pilot pressure and increased by lowering the pilot pressure. The PID control loop is set up with direct mode rather than indirect because pressure must be increased in response to an increase in flow.

An added advantage to using an Equilibar BPR in this way is that pressure changes downstream of the control valve are isolated and will not affect flow rate.

In the video, LabView displays key information to illustrate exactly what is happening. See it using this link.

Background Information:

The key to the ultra wide range of flow in this setup comes from the high resolution of the Equilibar dome-loaded back pressure regulator coupled with the Equilibar high resolution electro-pneumatic regulator. Working together, this combination responds to signal changes as small as 0.01% and controls the back pressure to a precision of greater than 1:100.

Most traditional control valves suitable for research and process industries are limited to a 10:1 or sometimes 15:1 ratio. Because new Coriolis and Thermal Mass Flowmeter technologies allow for measurement up to 100:1 flow rate ratios, engineers often need to install two parallel control valves to provide the required turndown. Equilibar’s wide range flow control technology offers a simpler and more elegant solution.

For more detailed information about using Equilibar devices for reliable and flexible flow control, visit our flow control page or read this Flow Control Magazine article. As always, we invite you to contact our engineers with your most challenging fluid control problems and questions.