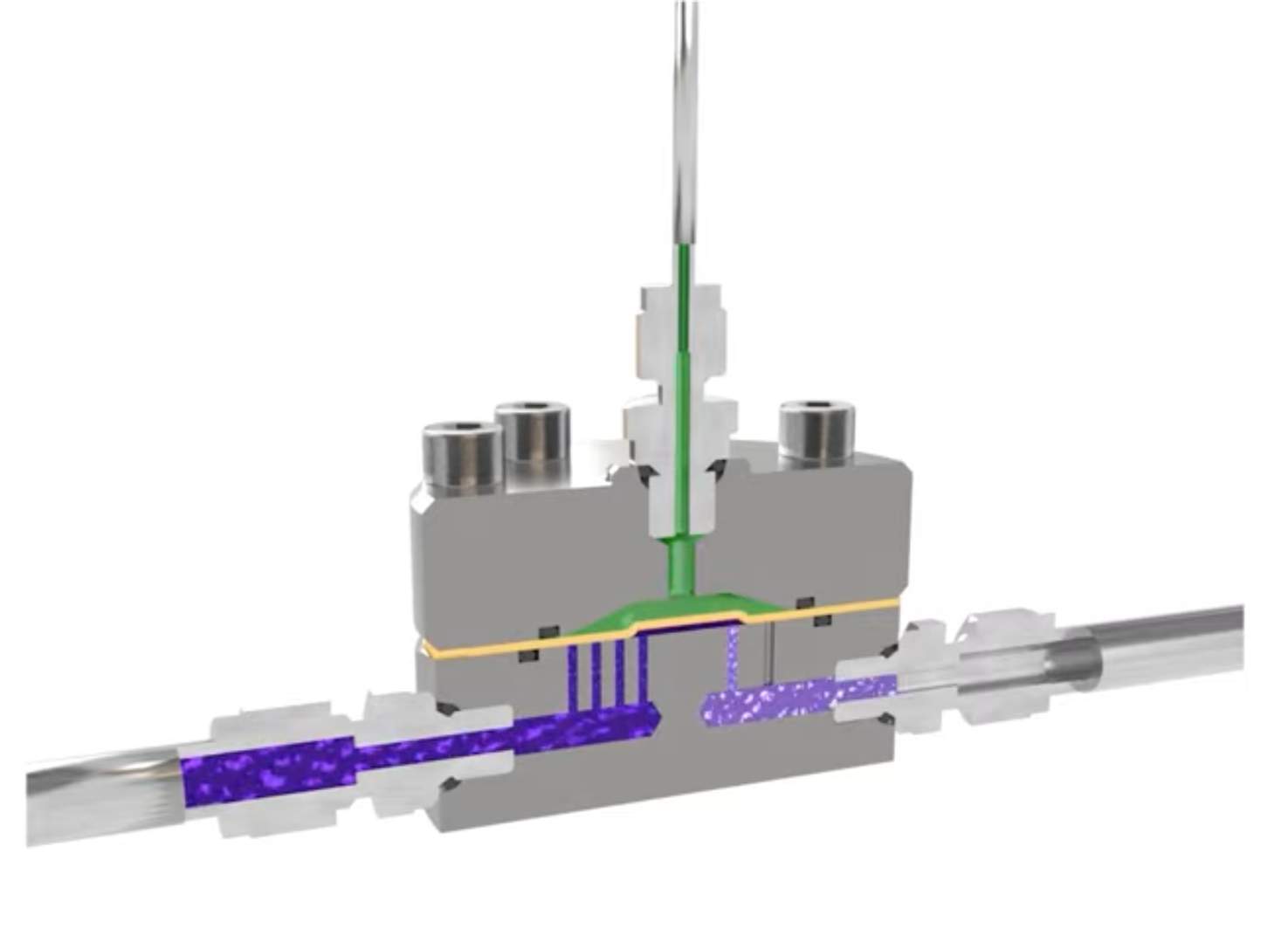

Equilibar’s Jennifer Jacober is a design engineer with expertise in flow control solutions for unusually complex applications. She recently helped create an animation video that demonstrates the inner workings of a new Advanced Flow Control Valve (AFC) with direct-sealing diaphragm technology. The valve has specific advantages for applications with multiple challenges and is especially useful for applications involving extremely wide flow rate ranges, multi-phase flows, exceptionally low or high differential pressures, and supercritical conditions.

In the following Q&A, Jennifer provides supplemental information for the video and gives examples of applications where this type of valve might be useful.

EQ: The new animation video goes inside an Equilibar® AFC valve and distinctly shows how the fluids flowing through it interact with the diaphragm and orifices. Have you had any feedback about how helpful this animation is in terms of understanding the technology?

Yes, several customers have told us that the animation helps them understand our unique technology. Our valve works in a completely different way than the traditional flow control valves that have been dominant in the industry since the 1800s, so it is useful to see how exactly our back pressure regulators work to modulate flow. Overall, the video does a good job showing that while our valve has unique advantages over traditional flow control solutions, it can be used in the same setups customers already have or are used to seeing.

EQ: Traditional types of flow control devices include rising stem globe-style valves, rotating ball valves, and slide gate valves. These valves usually offer variants for different process conditions, and, until recently, they were able to handle common flow control scenarios. What are the types of situations engineers run into today where traditional valves are not sufficient?

Traditionally, these conventional types of flow control valves have limited turn down ratios like 20:1 or 50:1 at their best. Customers who need to control across a wider flow range in one process line will often have multiple flow control valves that each control a different section of the total flow window. With an Equilibar® flow control valve, our multiple orifice technology, as shown in the animation, allows for a huge flow range to be controlled with one single valve. We commonly see up to 500:1 turndown ratio in the lab. At some point, our valve’s turndown ratio is limited by the resolution of the flowmeter that is being used in the feedback loop, so 100:1 turndown is typical with the AFC.

Our flow control valves can also offer the same benefits as our back pressure regulators—they can be designed for use in extreme environments like very high or very low temperatures and pressures. They can be designed for corrosive media, mixed phase fluid, or even media containing particulates. We also have single use and sanitary offerings for biological, pharmaceutical, and food and beverage applications.

EQ: How does the AFC perform in these demanding set-ups?

The benefits of the AFC really come from the multiple orifice design and the simplicity of the construction that allows for easy customization. With the proper selection of body and diaphragm materials, combined with responsive flow meters and control systems, our AFC can perform well in many demanding scenarios.

Some customers who are dosing ingredients into their process lines need extremely accurate flow control into a larger process line. Our sanitary valves are often constructed from Hastelloy with a PTFE diaphragm for sanitary liquid product blending applications that span from consumer products manufacturing all the way to pharmaceutical production. The resilient and compatible materials of construction allow our customers to use the valves with a wide range of fluids in different process conditions.

I think it’s also worth noting that many customers love how few parts the flow control valve has. It requires no calibration after you switch out the diaphragm and takes a fraction of the time to clean and changeover compared to a traditional flow control valve or a gear pump, etc.

EQ: What are some of the more exciting challenges you’ve worked on that have dramatically benefited from the AFC valve?

One application that stands out is a customer using our valves for deep oil well injection applications in North Dakota, which was featured in a Process Instrumentation magazine story. This customer needed to inject precise volumes of water into oil wells to prevent salt in the wells from crystalizing, ultimately impacting the crude oil yields. Because of huge pressure variations, and a wide flow range requirement, they needed a flow control valve with a 230:1 Cv range, which is beyond the capability of traditional globe style valves. Equilibar flow control valves were able to solve their problem.

In another application, a customer is studying corrosion of steel alloy materials used in carbon capture systems. Often hydrogen sulfide or other impurities are present in the CO2 and corrosion rates may increase or pitting failures may be a concern. Equilibar flow control valves are used to deliver varying amounts of impurities to the corrosion study chamber. Advantages of using an Equilibar valve are not only its fast response to changing setpoint needs and its capacity to operate across a wide range of test flow rates, Equilibar valves can also be manufactured with chemical resistant materials.

Beyond that, some exciting applications in development involve using other parameters as feedback in a PID loop. These could be signals like pH, conductivity, or temperature to indirectly control flow through different systems. This could potentially apply to a number of industries from electronics to biopharmaceutical production.

EQ: The video also shows how to use the AFC in conjunction with a flow meter, a PID loop and an electronic pressure regulator to control flow. How easy is it to set this up in the real world?

There are multiple configurations that work with our flow control valves. It is a choose-your-own-adventure that allows customers to use the control devices they are already comfortable with or what works best with their existing controls infrastructure. However, for all the configurations, we recommend that each customer has personnel on site who can help tune the PID loop to work best with their process conditions. Every application is different, and each customer will have different expectations for the speed and precision of the PID loop running our valve. Fast acting flow meters make a great combination with the Equilibar AFC. For more information, visit our Flow Control Page.

EQ: Do you foresee the AFC being adopted by industries other than those using it now? What do you envision for its future?

Watch the video below and as always, we invite you to get in touch with Jennifer or one of our application specialists to discuss your challenging fluid control application.