Equilibar’s direct-sealing diaphragm technology was first introduced to provide precise backpressure control for complex applications; however, engineers and scientists soon discovered that these devices can offer advantages for extremely complex flow control applications as well. Specifically, they perform well in applications involving wide flow rate ranges, corrosive chemicals, extreme pressures, multi-phase flows and supercritical states.

A new How It Works Page on the Equilibar website gives a comprehensive comparison of conventional flow control valves vs. Equilibar’s flow control technology to enable engineers and researchers to make the right choice for each application. Read on for a quick summary:

What is a control valve?

The term Control Valve is an umbrella label for any valve that provides control over the size of a fluid passage to regulate flow, pressure, or other process parameters related to flow. By adjusting a positioner or knob, the cross-sectional area (and thus the valve coefficient, Cv) can be changed to modulate the flow through the valve. Engineers often refer to the “% open” of a valve, which is an indication of the openness of the valve as a percentage of its fully opened state.

Control valves are commonly used in closed loop control setups where measurement of a process variable like pressure or flow is relayed to a PID controller, which then sends a command to an actuator or positioner to set a specific “% open” of the control valve. The use of closed loop control schemes allows control valves to be used for a variety of purposes: controlling flow, upstream pressure, downstream pressure, temperature, etc. They are often used in place of dedicated regulators due to this flexibility of use. Control valves can come in many different forms, including globe, butterfly, ball, pinch and diaphragm valves.

What is a pressure regulator?

Pressure Regulators work a bit differently, with their Cv being automatically adjusted to maintain a specific pressure setpoint. Often, a regulator applies the pressure of a controlled fluid against a diaphragm. The diaphragm opposes a compressed spring or other force to obtain a pressure balance at a selected setpoint. Pressure reducing regulators sense and control downstream pressure, while backpressure regulators sense and control upstream pressure.

How an Equilibar back pressure regulator works

Equilibar Back Pressure Regulators feature several key differences compared to traditional back pressure regulators, making them capable of providing precise flow control when configured accordingly.

Equilibar devices feature a thin and flexible diaphragm that seals on multiple orifices. A pilot pressure fluid (usually gas) is applied to the top of the diaphragm to maintain a pressure balance with the process fluid flowing through the Equilibar unit. As fluids flow through the unit, the Equilibar regulator holds the process pressure equal to the pilot setpoint pressure above the diaphragm. The diaphragm lifts off the orifices to release pressure as the upstream process pressure exceeds the setpoint pressure. When the flow is minimal, only a portion of one orifice will engage to release the pressure. When the flow is high, the diaphragm is pushed up to engage all the orifices.

In other words, the Equilibar valve varies its Cv, or its % openness, in response to variations in flow to keep the upstream pressure equal to the pilot pressure.

Benefits of the Equilibar design over traditional control valves

The simplicity and elegance of the Equilibar direct sealing diaphragm design results in many benefits over traditional control valves.

With the Equilibar valve, any fluctuation in flow leads to an immediate movement of the diaphragm as the Cv is adjusted instantaneously to keep pressure stable. By contrast, with a control valve in a closed loop control setup, there will always be some inherent delay between the measurement of the upstream pressure and the PID loop determining the command to output and then translating that command signal to adjust the valve Cv. In processes with rapid fluctuations in flow, this longer response time can cause undesirable pressure fluctuations.

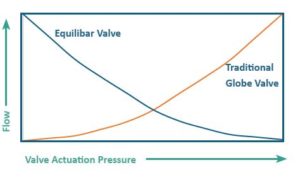

For control of all other process variables (flow, downstream pressure, temperature, etc), the Equilibar valve can be used in much the same way as a traditional control valve. Varying the reference pressure on the dome in relation to upstream pressure will raise or lower the diaphragm, effectively setting the % openness or Cv of the valve. To open the valve more, the dome pressure is reduced and to close the valve more, the dome pressure is increased. This results in a flow response vs. actuation curve that is the inverse of what you’d see with a globe valve.

Other considerations

While the direct-sealing diaphragm valve offers distinct advantages, implementing this approach involves several requirements, including an instrument gas supply and a pilot pressure regulator. It is important to consider all factors when making a choice.

Please see our new page for all the details: Compare Equilibar to Traditional Control Valves and, as always, we invite you to contact our experienced application engineers to discuss the specific requirements of your fluid control application.