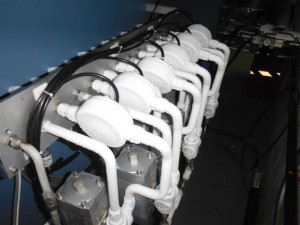

Equilibar precision back pressure regulators use innovative direct diaphragm sealing technology. The diaphragm is the only moving part. Equilibar engineers carefully select the diaphragm material to meet the extreme conditions that your application requires. All regulators are built from SS316L bar stock to handle the toughest operating conditions including extreme cold, high temperatures to 450 C, high pressures to 10,000psi, and unprotected outdoor installation. Pictured are six GS3 regulators controlling -40 C liquid fuel at pressures from 0 to 300psig. The frozen condensation makes for an interesting photograph.