Choosing the best method to control the flow of a pump can be complicated. There are several options, each with unique advantages and disadvantages.

The Equilibar website offers a number of resources for making a good selection. We also have information about the related topics of pulsation dampening, pump runaway, pump slip, and more.

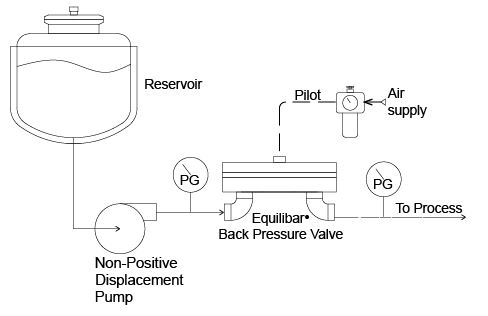

A good overview can be found on Equilibar’s Controlling the Flow of a Pump page. This summary describes several methods for pump flow control, such as using a recirculation loop (bypass line) along with a pressure bypass valve. Another method discussed is throttling the discharge by opening and closing a valve at the exit of the pump.

Advantages of Equilibar technology for controlling the flow of a pump

Equilibar instruments use a flexible diaphragm membrane as the only moving part. This eliminates friction to allow precise response with low hysteresis. Their rugged design is capable of handling extreme temperatures and corrosive chemistries. These are some of the reasons an engineer or scientist will select Equilibar for pump control.

For example, a complicated PID loop is sometimes used to provide electronic control of a centrifugal pump based on output from a flow meter. The modulating control element is usually a rising stem flow control valve or a variable frequency drive on the pump’s electric motor. In certain situations, however, an aggressive media requires a flow meter that is prohibitively expensive. A simpler pump flow control circuit using an Equilibar Back Pressure Regulator without the need for a flow meter offers distinct advantages.

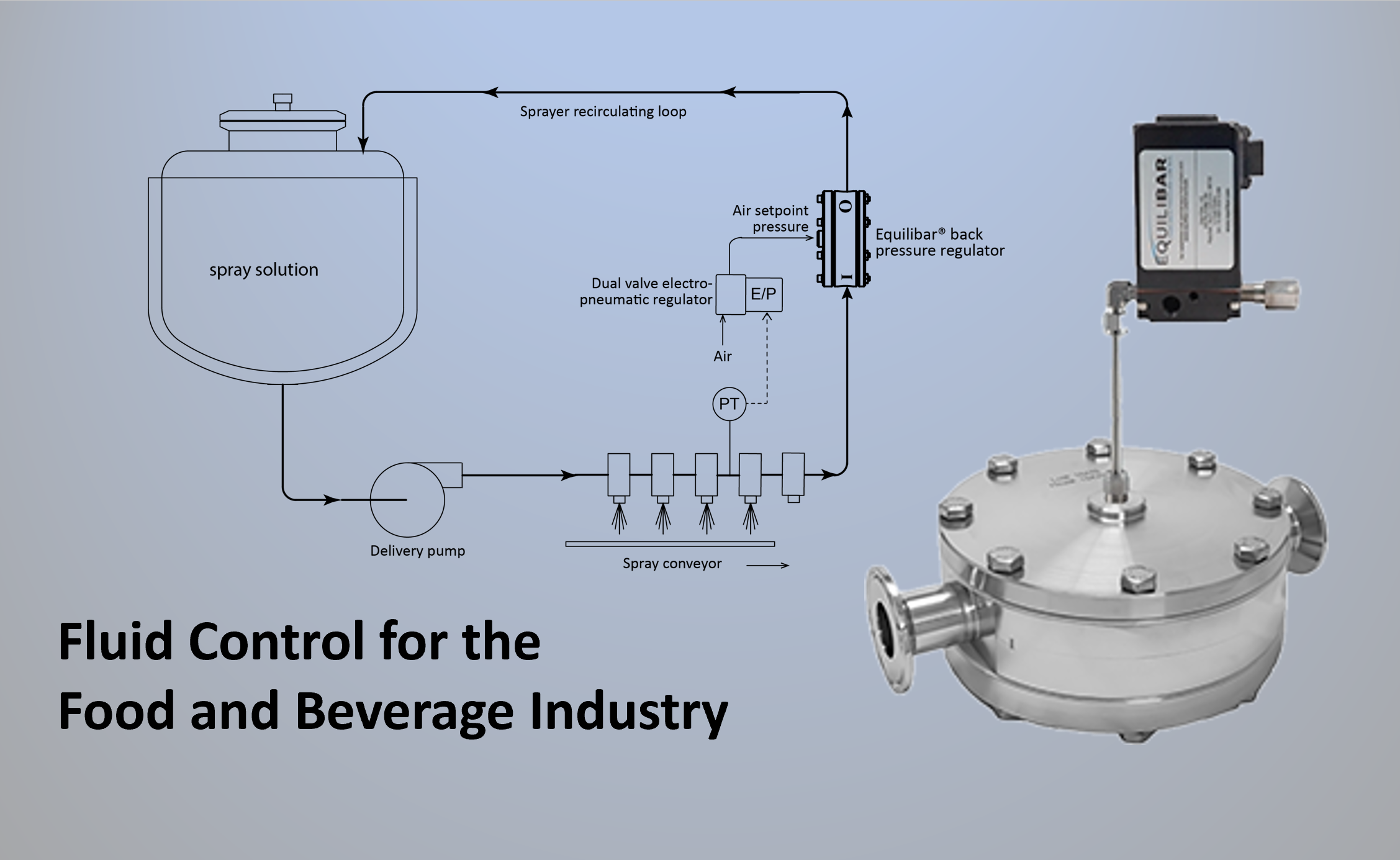

Sanitary considerations

In Biopharmaceutical applications such as chromatography and media transfer, a sanitary lobe pump is commonly used. Equilibar’s clients have reported good success using our technology at the discharge of their positive displacement pumps to prevent pump slip, which is also known as pump runaway. (See this explanation of pump runaway from the Petroleum Equipment Institute.) For these sanitary applications, Equilibar technology offers the advantages of high efficiency, reliability, CIP (Clean In Place) capability, and sanitary attributes.

For more examples of how to use Equilibar technology for controlling the flow of a pump, see the Pump Control Applications listing in our Popular Applications menu.

If you have a tricky application involving pump control, please don’t hesitate to contact our engineers to discuss your particular challenge. We look forward to solving complicated problems.