The petroleum industry has stringent requirements for pressure control during core analysis experiments, which involve tests of rock samples to determine oil and gas content.

In pyrolysis testing, rock samples are analyzed to measure the hydrocarbon content that can be evolved at different temperatures while maintaining a safe and consistent pressure. In related core flooding experiments, the rock’s permeability to gas, oil, and brine is measured.

Back pressure regulators are a key component of most core analysis applications. Many of these applications require that the sample reactor maintain constant pressure under no-flow conditions. A rock sample may evolve no gases during the early part of a temperature ramp-up, but it may later evolve significant flows of condensable hydrocarbon gases as the temperature rises, leading to quite complicated scenarios for researchers.

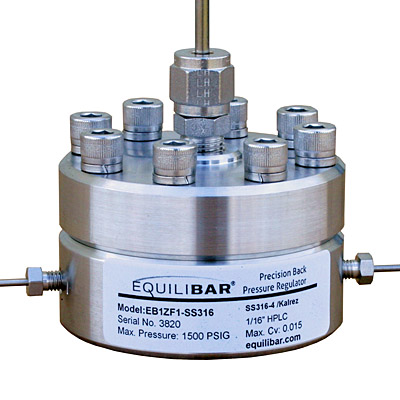

Equilibar’s Zero Flow (ZF) regulator is specifically designed to address the challenging requirements of the reservoir testing industry. Zero Flow regulators hold inlet pressures stable within about 0.5%, from true bubble-free zero flow up to the range of 1 liter/minute. These regulators have proven to be capable of addressing previously impossible application demands in core analysis and other research applications requiring micro-flow pressure control.

This is possible because Equilibar regulators rely on unique dome-loaded technology that has a supple diaphragm as the only moving part. In contrast, most traditional back pressure regulators rely on springs and other moving parts that can introduce friction and hysteresis. In the Zero Flow regulator, a soft-seal elastomeric O-ring is used to accomplish the ultra-tight closure. FKM is standard, with FFKM also in stock. The ZF is available SS316 or other alloys such as Hastelloy.

Equilibar engineers are knowledgeable about the challenge of maintaining precise pressure control during core reservoir testing. They are eager to talk about a specific application’s scenario. Feel free to contact them at inquiry@equilibar.com .