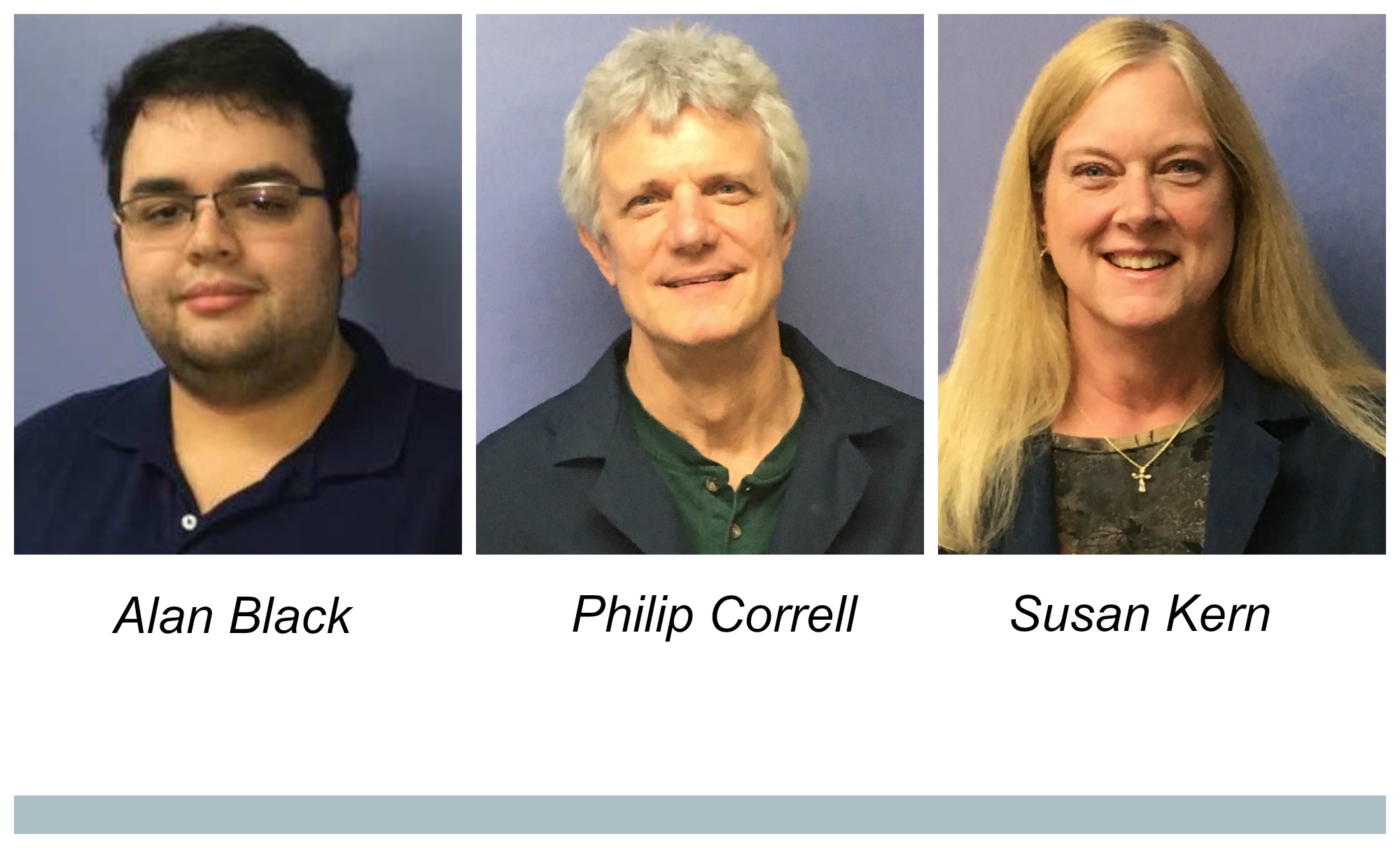

Equilibar’s newest customer response team members help us provide the ultimate level of customer support. It is our pleasure to introduce them:

Alan Black, application engineer, has a degree in physics from North Carolina State University where he did undergraduate research in computational astrophysics. His aptitude for complicated pressure control challenges was apparent from Day One. He quickly began assisting with quotes and is now working directly with customers. “I like being able to solve interesting and complicated problems for our customers,” he said. “I’d like to keep learning about different problems in pressure control and I hope to contribute my computational modeling skills to the company.” alanblack@equilibar.com

Philip Correll has a bachelor of engineering technology degree from the University of North Carolina at Charlotte and has worked in the computer, electronics and robotics field for more than 30 years. He has quickly become our specialist in testing systems and has completed a vendor training program to support the electronic regulators we use in our systems. Philip’s work is allowing us to explore new automation options as we provide pressure control for more types of applications. philipcorrell@equilibar.com

Susan Kern, office and sales assistant, joined our team in the fall. Her key responsibilities are to ensure that customers receive everything they need with their quotes and to support our engineers in customer communication. Susan has more than 20 years of experience with administrative and customer service work, and we have already come to rely on her strong skill set. susankern@equilibar.com